TABLE OF CONTENTS

Before Duro

After Duro

- Managed part revisions manually in Google Drive.

- No centralized source of truth for part data, drawings, or sourcing information.

- Slow and error-prone quoting and procurement processes.

- Supply chain team lacked visibility into the latest designs and part details.

- Scaling growth and product launches were difficult, limiting visibility for new team members.

- Manual workflows hindered agile hardware development and cross-team collaboration.

- Direct Onshape integration with one-click part releases into Duro.

- Part revisions instantly accessible—frozen in time and linkable to CAD.

- Supply chain team can access drawings, part numbers, and sourcing info without engineering.

- Faster quoting, ordering, and collaboration.

- Drastically improved time-to-order, from drawing to part delivery.

- Grew annual recurring revenue 3× per year over the past two years.

“With Duro, one of the biggest improvements we've seen is just the team can move so much faster. The time it takes us to go from drawing to sending parts out to quote to getting parts on order has been drastically improved.”

Caitlin Reyda, Engineering Program Manager, Lumafield

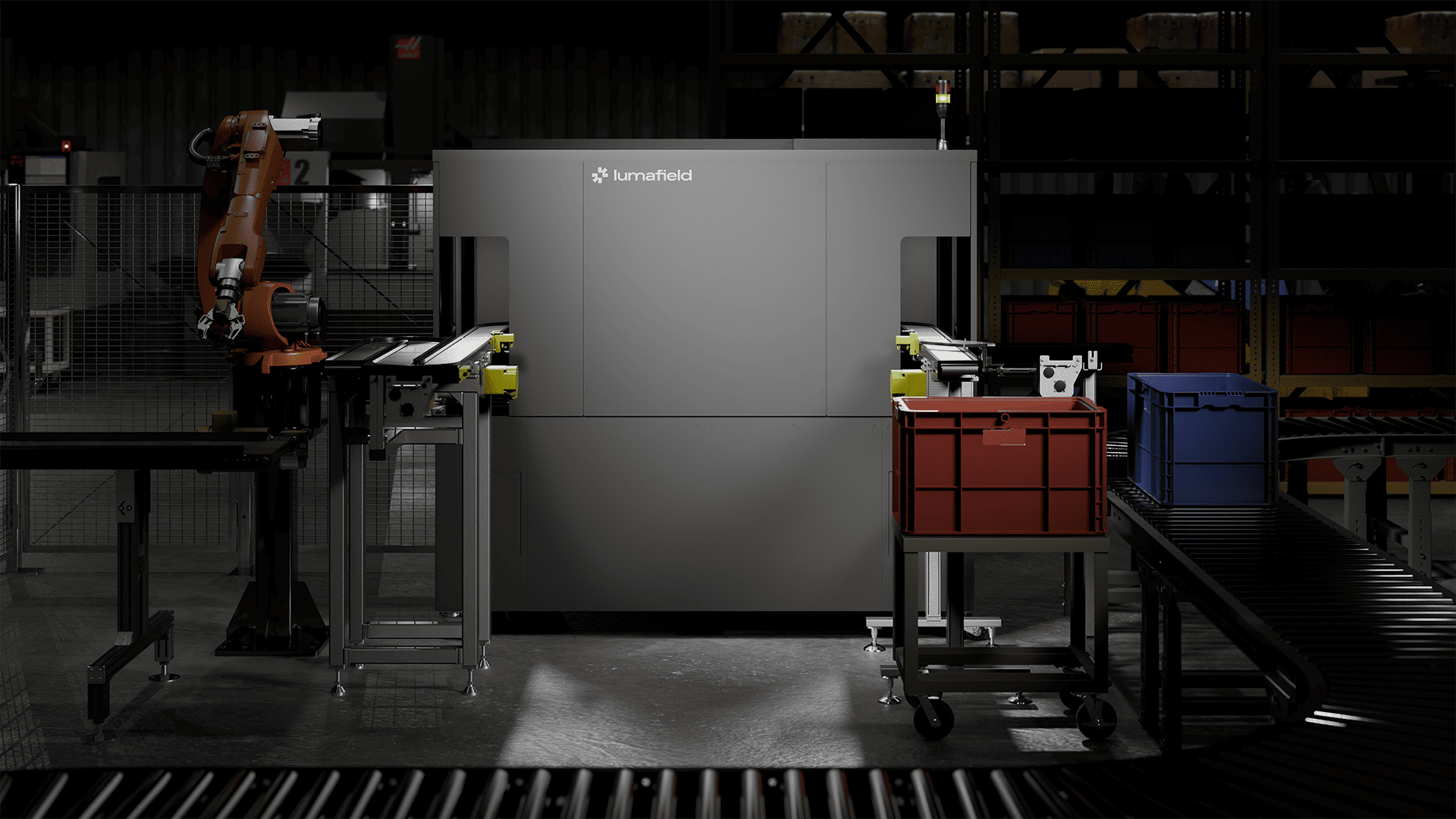

Bringing Industrial CT from the Lab to the Factory Floor

Lumafield is building next-generation CT scanning technology to bring powerful insights to every stage of the product development lifecycle—from initial design to full-scale production. Their Neptune and Triton CT scanners, paired with Voyager cloud software and Atlas AI co-pilot, allow manufacturers to inspect internal structures, catch defects early, and make confident go/no-go decisions. Engineers can look inside their products, check invisible features, and pinpoint problems before anything reaches customers.

Combining industrial X-ray CT scanners with AI-powered analysis tools, Lumafield allows manufacturers to detect flaws before they escalate into costly failures and recalls. Customers include fast-growing leaders in electric vehicles, medical devices, athletic equipment, and consumer packaging. For many, Lumafield is opening the door to CT scanning for the first time, making advanced, cloud-connected inspection accessible and collaborative for a new generation of product innovators.

“One of our favorite statistics is that 85% of our customers have never used CT before. By offering lower-cost, easy-to-use, cloud-based solutions, we help teams take advantage of this game-changing technology.”

Dan Pipe-Mazo, Head of Engineering, Lumafield

Challenges Before Implementation

As Lumafield expanded access to industrial CT scanning, its internal processes were slowing it down. Part revisions were managed manually in Google Drive, with no centralized source of truth for drawings, sourcing details, or CAD files. Sourcing information was scattered, and procurement relied on back-and-forth between teams, leading to quoting delays and errors.

Lumafield’s agile hardware-software development cycles demanded better tools, but existing systems were siloed and hard to navigate. Supply chain teams couldn’t easily access the latest designs, while engineers spent time fielding repetitive questions.

Lumafield lacked a single source of truth and digital thread for revision management, which would unify documentation, support revision control, and help them move faster without compromising accuracy.

“Before Duro, sourcing information and part data were scattered across different documents. It was slow, manual, and easy to make mistakes. We needed a single place where the whole team could find what they needed without chasing things down.”

Caitlin Reyda, Engineering Program Manager, Lumafield

Post Implementation Improvements

Lumafield quickly onboarded 20+ users across engineering, manufacturing, and supply chain, running agile, synchronized cycles on a shared platform that supports the entire part development lifecycle.

With a direct Onshape integration, engineers can release parts with one click, making revisions instantly accessible and enabling the supply chain team to place orders faster, without pinging engineering for details.

Duro now serves as a single source of truth for all part data and documentation, making it easy for team members to check drawings, approvals, and part details without digging through emails or folders. This alignment has significantly improved quoting and procurement speed, reduced errors, and eliminated repetitive questions.

“One of the things we really like is the integration with Onshape. We use Onshape for our CAD system, and releasing a part and having the parts automatically appear in Duro was a game-changer for us.”

Caitlin Reyda, Engineering Program Manager, Lumafield

Lumafield Growth & Success

Backed by $75M in Series C funding, Lumafield has rapidly expanded the reach of its industrial CT scanners, tripling annual recurring revenue over the past two years and launching breakthroughs like Ultra-Fast CT, which reduces scan times by more than 100x.

These achievements—and a combined hardware/software business model—have positioned Lumafield as a leader in accessible, high-impact X-ray technology, with 85% of customers adopting CT scanning for the first time.

Lumafield’s technology is now trusted by top innovators across industries where precision and reliability are critical—from next-gen transportation to healthcare and advanced manufacturing. As global supply chains evolve, Lumafield’s solutions are helping manufacturers raise quality standards and reduce costly failures.

What’s Next for Lumafield?

Lumafield opened a new office in Los Angeles, designed as a hands-on showroom to welcome customers and showcase its CT technology. The company is accelerating its push into factory applications by embedding high-resolution inspection directly into production lines, turning quality control into a strategic advantage and enabling engineers to deliver breakthrough products without manufacturing defects.

Lumafield is deploying its Neptune and Triton systems to product development teams, quality labs, and manufacturing sites worldwide, while continuing to reduce scan times and automate decision-making through machine learning and AI.

With exciting new products in development for 2025, Lumafield sees Duro as a core partner in closing the loop between design and manufacturing, rapidly implementing new features, and supporting their agile roadmap.

“One of the things we’re looking forward to in the Duro roadmap is the ability to add more configurability. It’s been really promising to see how quickly they address our feedback, and it feels like we’re building a solution together that will work for our needs.”

Caitlin Reyda, Engineering Program Manager, Lumafield