TABLE OF CONTENTS

It’s an exciting time to work in manufacturing. Emerging cloud applications, automations, open APIs, and now AI are making it easier than ever to share data and make informed product decisions. AI is set to be a revolutionary tool for manufacturers, especially when coupled with the right Product Lifecycle Management (PLM) software.

Here are 5 predictions for how AI will revolutionize PLM in the near future, which will accelerate growth and innovation for manufacturing companies:

- More Advanced and Accessible Search Capabilities. AI will soon allow PLM users to search across vast data repositories using natural language rather than more complex key-value pairs.

- BOM Analysis and Optimization. Gen AI-assisted PLM software will help users fully optimize their Bill of Materials (BOM) for cost, lead time, or weight, for example.

- Generating New Product Versions. AI will soon be able to generate new product designs by combining existing design data with production data, supply chain data, requirements, and customer feedback.

- Demand Forecasting. AI plus PLM will empower manufacturing companies to optimize their development processes to meet customer demand.

- Preemptive Supply Chain Issue Identification. AI systems within PLM will provide easier access to supply chain information, which will help manufacturers make proactive decisions about which components to use in designs.

What is Generative Artificial Intelligence?

Generative AI (Gen AI) refers to artificial intelligence systems that generate original content, by using machine-learning models to evaluate patterns from large data sets. Gen AI can process a high volume of bespoke and unstructured data at unparalleled speeds.

The promise is to unlock capabilities that have never been accessible before, at least not in an efficient and timely manner. Gen AI is also interactive; users are able to engage with the system and provide training data, in order to shape and refine the generated content according to their needs.

Gen AI shows such promise, that one estimate anticipates the market for AI in manufacturing to be valued at $20.8 billion by 2028, up from an estimate of $3.2 billion in 2023.

Challenges Facing Manufacturers

As anyone who works in manufacturing knows, the path from design to production is seldom linear. Manufacturers are under pressure to keep up with the demand for impressive new technology while juggling supply chain volatility, increasing volumes of data, and demand forecasting complexity.

Product Development Complexity

Product development becomes increasingly complex year after year. Manufactured products are no longer primarily mechanical devices, but systems of interconnected software. Products now resemble electro-mechanical devices that contain numerous modules, including hardware components sourced from external suppliers. Managing all of the data necessary to design, manufacture and maintain such intricate, interconnected products across their lifecycle is a vast undertaking.

Supply Chain Challenges

There are many variables outside of a manufacturer’s control that impact the supply chain. Adverse weather, political events, and regulatory requirements can cause setbacks to a production schedule. Companies do their best to manage these challenges but there are only so many hours in the day that can be spent processing all the information that’s necessary to fully optimize for lead time and pricing.

High Volume of Bespoke and Unstructured Data Silos

Companies need to source and process data from the design, supply chain, and manufacturing teams, factoring in disparate data from electrical and mechanical design tools as well as requirements and sourcing information. Given the sheer amount of data, it can be difficult for hardware teams to find all the necessary product-related information, much less process all of that data in order to optimize their product designs for time and cost.

Where AI Excels and How it Impacts Manufacturing

AI will soon be able to help manufacturers better understand their vast supplies of data. Manufacturers will be able to answer complex product questions, optimize their BOMs, and quickly adapt to supply chain disruptions. When integrated with a Cloud PLM such as Duro, AI in supply chain management will allow for faster, more informed decision-making in product development.

The Marriage between Gen AI and PLM

PLM is the perfect place to apply Gen AI technologies, as PLM is fundamentally a data management platform that aggregates diverse data from design, supply chain, and manufacturing teams. This data comes from different sources and formats, so integration and analysis can be labor-intensive.

Duro, a Cloud PLM, already excels in this area by using a plug-and-play architecture that removes the need for custom configurations between applications. It integrates data from various sources, including CAD tools, ERP systems, and sourcing suppliers. Duro also connects with Manufacturing Execution Systems (MES) and quality management tools.

Gen AI has the potential to further enhance these capabilities by efficiently processing high volumes of unstructured data, and enabling advanced search and analysis functions.

5 Ways AI Will Revolutionize PLM and Product Development Processes

As mentioned above, high volumes of information from disparate sources creates complexities for manufacturing companies. Engineering teams don’t have the time to process every piece of information necessary to optimize their product design and production. This is where Gen AI has the potential to augment PLM.

1 - More Advanced and Accessible Search Capabilities

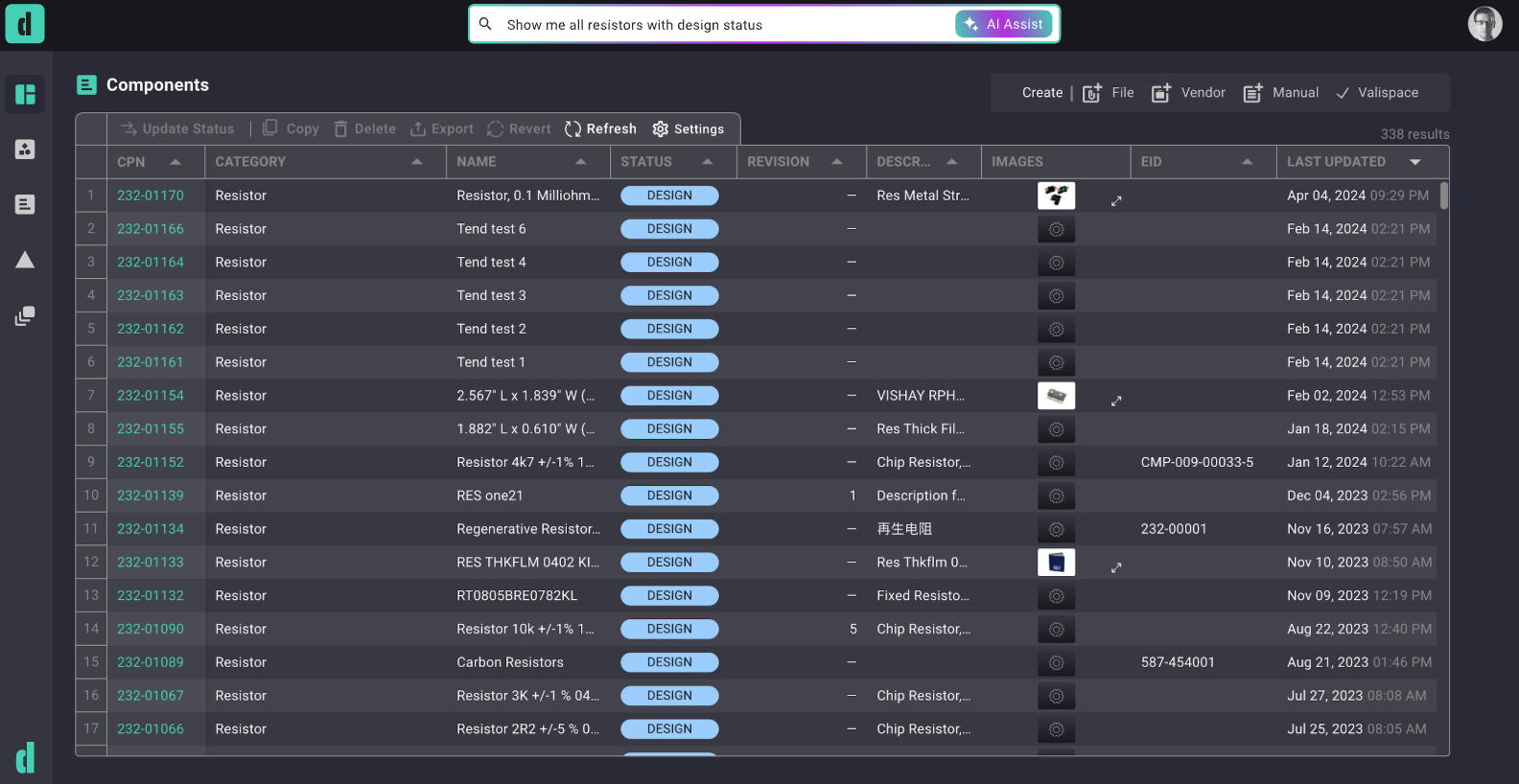

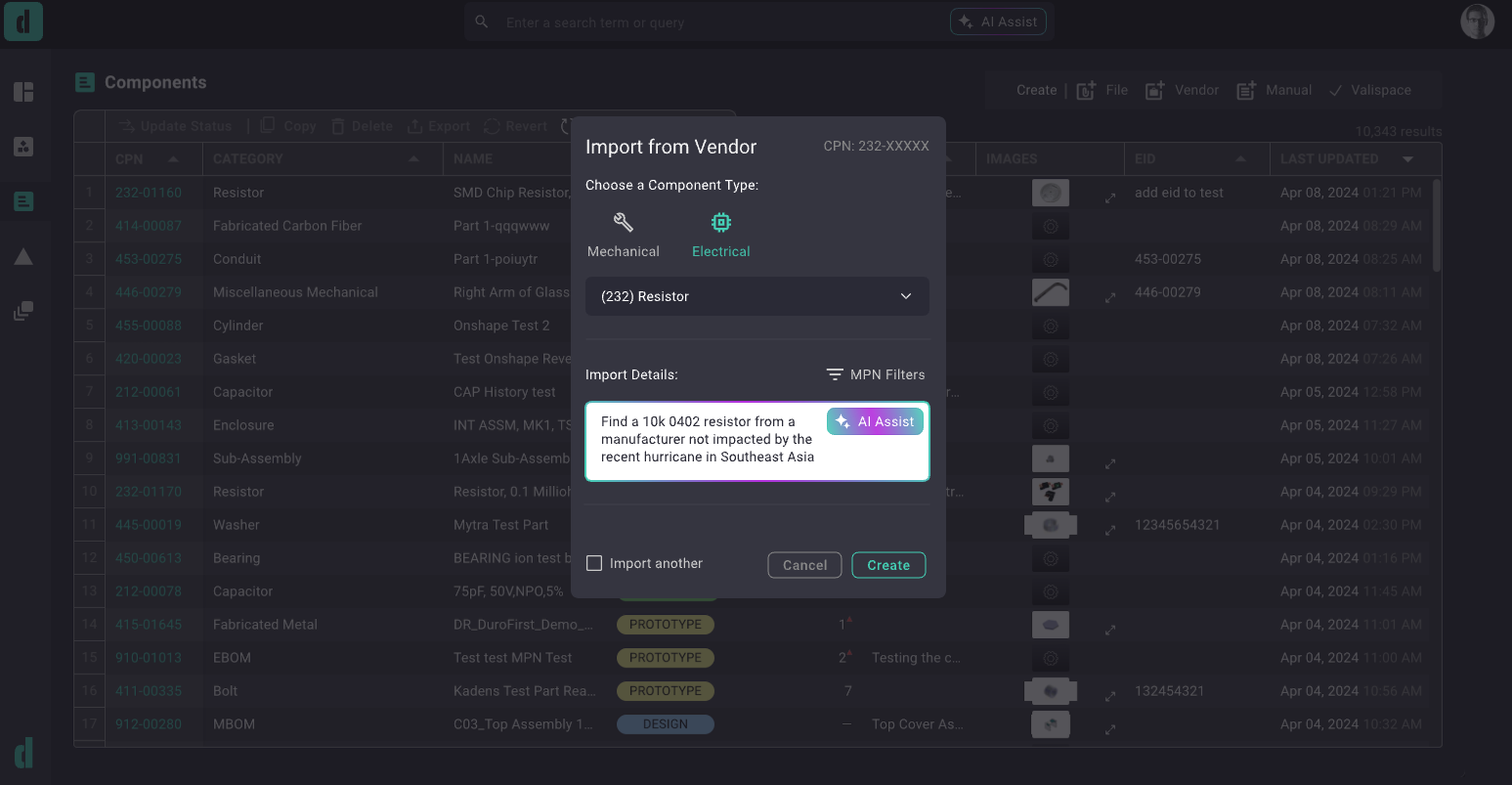

Gen AI with natural language processing shows promise in helping lower the threshold of technical knowledge necessary to perform searches within PLM systems. Instead of requiring key value pairs, Gen AI will soon allow any user to ask a question in terms that make sense to them. The user will then be able to further fine tune this search with more and more criteria in a process that feels intuitive rather than technical.

For example, say an engineer wants to search their BOMs for CMP resistors that are still in the design stage. They might search their PLM for “type:CMP cat:resistors status:design,” and the relevant parts would come up. This is easy enough for an engineer who’s knowledgeable about the product, but not as easy for another team member who doesn’t know the right keywords. Gen AI with natural language processing will hopefully soon make it possible for this team member to search their PLM using plain language, such as, “show me all the resistors we’re currently designing.”

This capability means that any team member can quickly find the information they need, without being an expert on the product. Supply chain managers or manufacturers can quickly search for data without having to go through lengthy product trainings or waiting for development teams to create complex search queries.

2 - BOM Analysis and Optimization

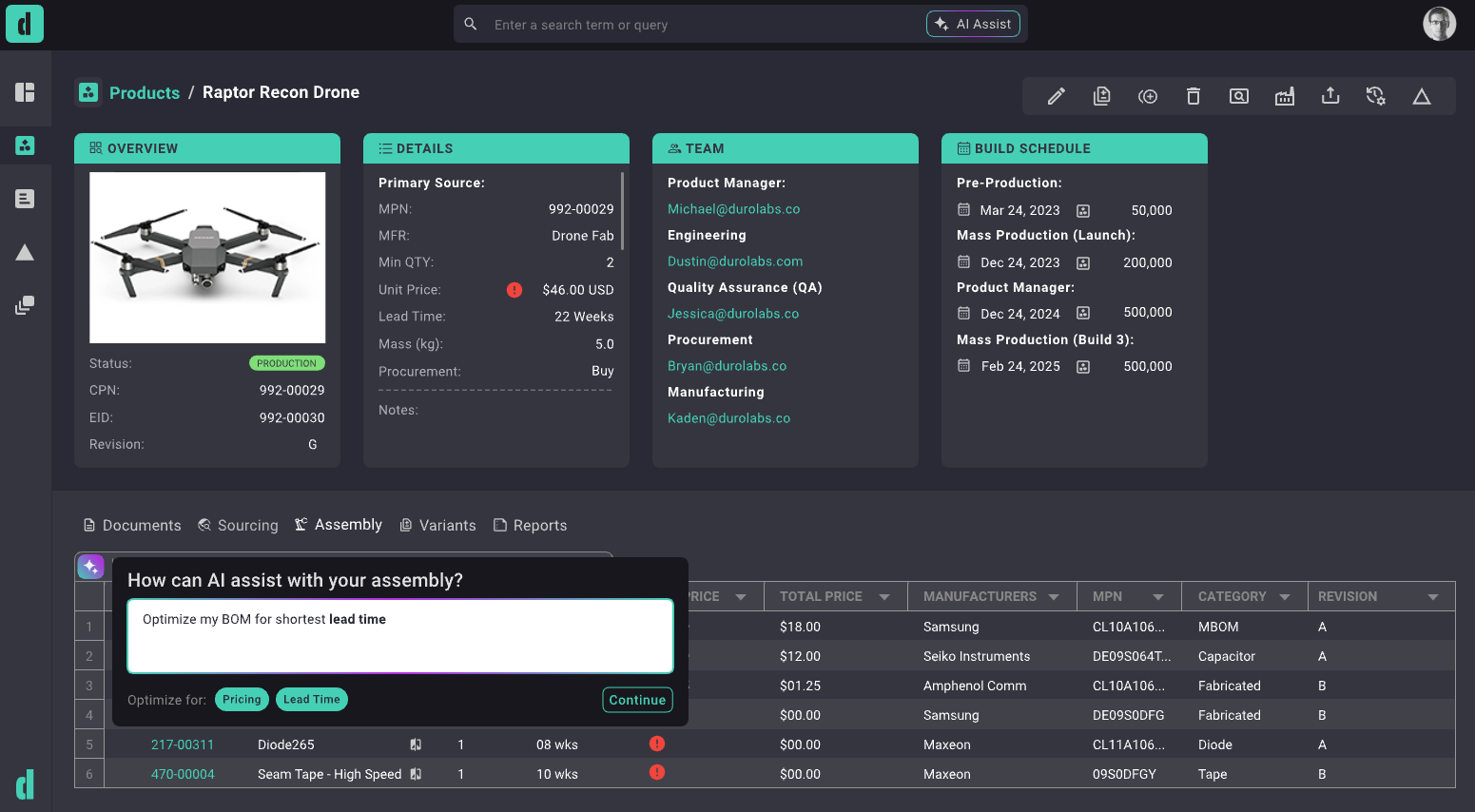

Gen AI-assisted PLM software is also promising for BOM optimization. AI’s ability to process and cross-correlate vast amounts of internal and external data will soon allow manufacturing teams to easily ask questions that factor in data from disparate systems. This would allow companies to streamline their product components to meet certain criteria, such as a production timeline or for cost.

Say there was a weather event an engineering team wanted to get ahead of. An AI-partnered PLM could allow the team to easily scan their product BOMs for components produced in the weather-affected region, and then look for manufacturers in unaffected regions.

The possibilities for Gen AI-assisted BOM optimization are huge; soon, teams might be able to ask their PLM questions like:

- “Which existing design is closest to meeting the new requirements?”

- “Which components meet the specs and are available in 10 days?”

- “What are the consequences on the budget of making this pending change?”

- “Which current or legacy products use part number 001-78963?”

- “Optimize this BOM for cost, availability, lead time, brand X…”

- “Release the BOM from engineering and initiate all downstream processes including procurement, to meet NPI date.”

3 - Generating New Products and Iterations

Taking AI’s potential one step further, users might soon be able to ask their AI-assisted PLM complex product design queries. In other words, engineers could ask their system to generate new product designs by combining existing design data with production data, supply chain data, and even customer feedback.

For example, engineers could ask their systems questions like, “Design a version of this existing US-based product that we launched last year, but make it for the European market and address any local regulations or design preferences. And design it with the goal of improving first pass yield by 5%.”

4 - Demand Forecasting

Gen AI also has the potential to assist with demand forecasting. Companies will soon be able to use AI to analyze historical sales metrics, trends in the market, and feedback ratings. Once AI is integrated into PLM, manufacturers will be able to optimize their designs and production processes for this demand-related data in addition to BOM optimization.

This will enhance manufacturers’ ability to make informed design and production decisions and more effectively plan new product introduction (NPI), as well as mitigate the risks associated with over- or under-production.

5 - Preemptive Supply Chain Issue Identification

Another promising use for Gen AI within a PLM system is the ability to solve complex parametric problems, such as supply chain challenges. This will empower procurement officers and other team members to be proactive about impending supply chain risks that might impact their productions, rather than reactive.

Imagine a procurement manager walks into their office one morning and sees a message. Their Gen AI-powered PLM system has identified a high typhoon season predicted in Southeast Asia, and several parts for a new product are coming from a supplier in that area. The PLM system recommends another supplier from a different region instead. The components will be identical and keep production on track, side-stepping a potential months-long production delay.

The Future of Manufacturing with AI

At Duro, we’re excited about Gen AI’s transformative potential to revolutionize the hardware and manufacturing industry. AI demonstrates tremendous promise in enabling design and procurement teams to achieve a more streamlined and efficient path from design to production.

As AI continues to accelerate growth in manufacturing, it’s important for hardware teams to partner with modern PLM solutions that are high-performing, flexible, and lightweight to allow for innovation within the platform.

Duro’s AI-enabled cloud-native PLM is designed for today’s product development needs. It combines engineering processes and AI with rich supply chain data to help make better products faster. Our intuitive PLM platform empowers teams to continually optimize their product development and manufacturing processes.