TABLE OF CONTENTS

The modern supply chain often includes multiple suppliers, manufacturers, and distributors networks, where even minor disruptions can lead to significant delays or shortages. As global markets become more complex, businesses are adopting artificial intelligence (AI) to tackle issues and avoid all too common supply chain disruptions.

This change is happening fast, with 95% of data-driven decisions set to be partially automated. AI is quickly becoming a standard tool for hardware and manufacturing companies looking to predict potential disruptions, optimize logistics networks, and respond to unforeseen events with agility.

This article examines AI’s role in reshaping supply chains and how manufacturers can leverage AI-powered systems, such as generative AI and predictive analytics, to optimize production, improve logistics, and build more resilient operations. We also examine how companies use PLM software to simplify and automate supply chain workflows.

What is AI’s role in the Supply Chain?

In the global market, supply chains are no longer just operational necessities; they are pivotal to achieving broader business goals like cost efficiency, competitive differentiation, and customer satisfaction. Hardware and manufacturing companies must take a proactive and integrated approach to their supply chains to thrive.

Using AI systems to process supply chain data allows companies to optimize their supply chains. AI can process endless information and continuously improve its ability to detect patterns and predict outcomes. It’s extremely useful for identifying inefficiencies, mitigating risks, and suggesting practical solutions.

AI can analyze logistics data to anticipate delays, such as port closures or weather events, and recommend alternate shipping routes to ensure on-time deliveries. It can also help companies quickly identify alternative suppliers by analyzing supplier finances, customer ratings, sustainability metrics, and real-time news alerts. AI is now being used to negotiate with suppliers, which is useful for large enterprises that devote significant resources to supplier communications.

How Does AI affect Supply Chain Performance?

AI helps hardware and manufacturing companies streamline operations and tackle challenges more efficiently and accurately. Generative AI, in particular, allows hardware companies to model possible supply chain issues to preempt them. AI can analyze data to predict supply chain disruptions, accurately forecast demand, adjust production schedules for peak efficiency, and monitor machine performance.

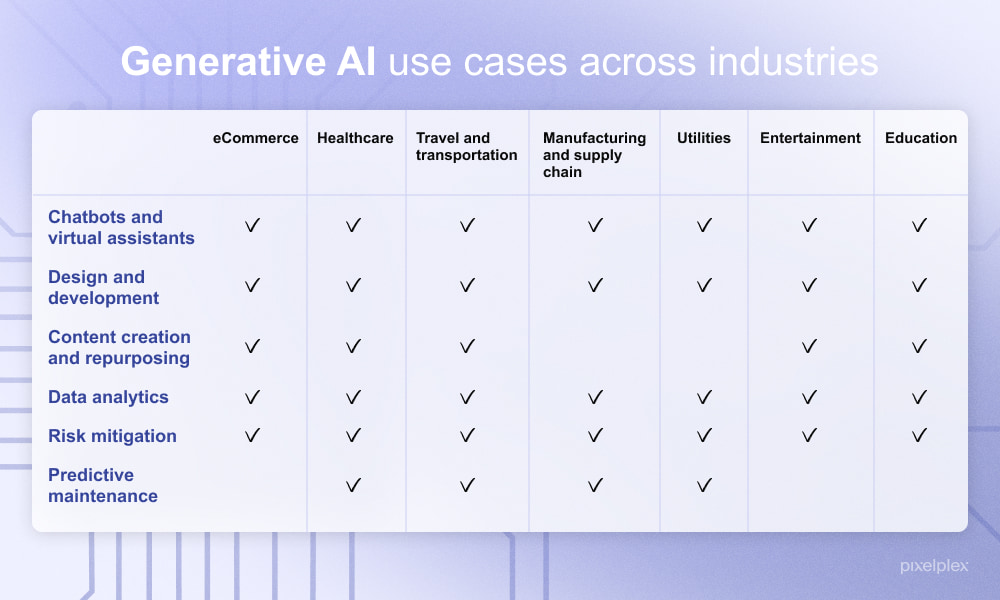

Generative AI in the supply chain

Generative AI (GenAI) is an emerging technology that is reshaping supply chain management. By leveraging large language models and other generative tools, companies can simulate complex supply chain scenarios, identify risks, and test strategies before implementing them. Generative AI can help manufacturers model the impact of supplier shutdowns or material shortages and develop contingency plans in advance.

GenAI facilitates better decision-making in the supply chain by processing large amounts of data and presenting actionable insights in an easily digestible format. Whether suggesting optimal inventory levels or identifying alternative suppliers, GenAI enables businesses to remain agile in the face of uncertainty. As generative AI advances, its role in enhancing supply chain resilience and efficiency will continue to grow.

Mitigating Disruptions with AI

By analyzing historical and real-time data, AI can predict disruptions in supply chains, such as supplier delays or extreme weather events, and recommend contingency plans. AI in procurement plays a critical role here by identifying alternative suppliers, optimizing purchasing decisions, and ensuring the timely delivery of materials.

Manufacturers can use AI to anticipate delays in raw material shipments or factory shutdowns, allowing them to adjust sourcing or production schedules proactively. AI models can analyze weather patterns or logistical bottlenecks to recommend alternate sourcing options or adjust production schedules, minimizing the operational impact.

Demand Forecasting and Planning

Enhanced demand forecasting helps manufacturers align production with market demand. For example, robotics companies can use AI to analyze order trends, component availability, and production capacity. This enables them to adjust production schedules, ensuring they meet customer demand without overproducing or running into supply shortages. This precision allows for smoother operations and better use of resources.

Logistics Optimization in Manufacturing

AI supports manufacturing operations by closely monitoring production processes and equipment health, identifying potential issues, and alerting teams before problems escalate. Manufacturers use AI-driven predictive maintenance to track machinery performance across their factories. When a machine shows signs of wear, AI alerts the team to schedule repairs, preventing expensive breakdowns and reducing downtime.

Predictive analytics also help minimize unexpected expenses by identifying potential bottlenecks early. AI systems can flag when a part will run out of stock, preventing costly rush shipments or unscheduled production halts for repairs.

AI in Supply Chain Examples

Real-world applications of AI in the supply chain are already delivering impressive results. Manufacturing companies are enhancing their supply chain management by integrating PLM (product lifecycle management) powered by AI to optimize production planning, control inventory, and improve overall supply chain visibility.

Supply chain workflows

Companies like Rapid Robotics use AI to streamline workflows by automating repetitive manufacturing tasks. By integrating AI with production lines, they eliminate bottlenecks caused by manual intervention, enabling faster production timelines and more reliable delivery schedules for their customers. Rapid Robotics recently introduced Rapid ID, a robotic solution for the supply chain powered by Gen AI and 3D vision, further enhancing precision and efficiency.

Smart warehouses

Large e-commerce platforms use AI to anticipate shopping trends and adjust inventory levels, ensuring their supply chains remain responsive and well-stocked. By leveraging these insights, manufacturers and suppliers can effectively align their operations to meet consumer demand.

Retail forecasting

AI-powered robots handle picking, packing, and sorting tasks with unmatched accuracy and speed, cutting down on human error and labor costs. AI ensures supply chain efficiency by accelerating order fulfillment times and reducing errors that could delay shipments. This capability enables manufacturers and distributors to meet customer demand better while optimizing their supply chain operations.

Shipping logistics

Shipping companies are employing AI to navigate severe weather and other local disruptions. AI monitors weather patterns, dynamically reassigns delivery vehicles, and forecasts issues such as road closures, thereby maintaining delivery schedules.

The Future of AI in Supply Chain

The use of AI in supply chain management marks a new era of enhanced agility, sustainability, and efficiency as technology reshapes traditional processes and delivers enhanced solutions. With tools like predictive analytics to anticipate disruptions and generative AI for modeling complex scenarios, AI fundamentally enhances production planning, logistics, and operations across manufacturing sectors.

In 2024, aerospace and robotics industry trends demonstrated that these sectors greatly benefit from adopting AI and PLM software to enhance operations and reduce disruptions. This integration enhances real-time visibility and proactive decision-making capabilities, enabling these industries to predict and manage potential supply chain issues more effectively, including part shortages and shipping delays.

As AI technologies evolve, hardware solutions like PLM become essential for integrating these innovations into everyday supply chain management. By leveraging AI and PLM, companies can improve visibility and collaboration and streamline operations, setting new standards in efficiency. Adopting PLM software helps businesses maintain a competitive edge and future-proof their supply chains against upcoming industry shifts, ensuring resilience and adaptability.