TABLE OF CONTENTS

LA-based startup Beamlink is quietly solving internet connectivity for half the world by helping carriers expand to rural and disaster-prone communities. They aim to unlock 3.5 billion new subscribers and empower these communities to advance everything from education to healthcare.

Beamlink’s towers use less power than a lightbulb and auto-calibrate when plugged in. These compact devices don’t rely on existing infrastructure, making them easier for engineers to manage. Pocket networks of Bentocells cover areas at just 1% of the cost of traditional networks.

As one of our most innovative clients, we wanted to share the creative work Beamlink is doing to disrupt traditional cellular infrastructure. We chatted with Arpad Kovesdy, the Co-founder and CTO, to see how their technology is solving the global problem of internet activity and how PLM is helping them achieve this.

Rethinking Cellular Connectivity

Beamlink’s mission is to democratize cellular network access, making it affordable and accessible even in remote areas where current infrastructure is unreliable or too expensive. Beamlink takes the technology used in traditional cell towers and packages it into a small, low-cost device called the Bentocell.

These devices can bring internet to new places and re-establish connectivity in disasters and emergencies, all within about 5 minutes of setup. Arpad explained, “Cell towers as we know them haven’t changed in decades. They’re expensive, complex, and not always resilient. We wanted to change that. Half the world doesn’t have the luxury of the internet, which is hard to believe”.

Beamlink’s competitors are traditional cell towers, which build $2M towers on 60-foot metal poles requiring municipal power and trained engineers. Compare that to Beamlink’s towers, which are the size of a lunch box, operate on battery and solar panels, and are made for just $2K each–making them perfect for rural communities.

Beamlink Hardware Challenges

Beamlink designs and manages everything in-house, from custom circuit boards to the enclosures of their devices. Managing this complexity became more challenging as production scaled. “We build every single level of the hardware ourselves,” said Arpad. “But as we grew, it became harder to sync up the different versions of our designs, especially when sharing files with manufacturers.”

Beamlink managed its Bill of Materials (BOMs) using Excel spreadsheets and shared files via a previous vendor, which presented challenges, especially when exporting files. Version control was a big pain point for Beamlink. Without a centralized system, email threads and duplicate files piled up, often leading to confusion.

“We’d send manufacturers ZIP files with design revisions, but sometimes they’d start building the wrong version,” Arpad explained. “Luckily, we caught the mistake in time, but it showed us how urgently we needed a better system. That’s when we decided to invest in PLM software with PDM.”

Why Beamlink Chose Duro

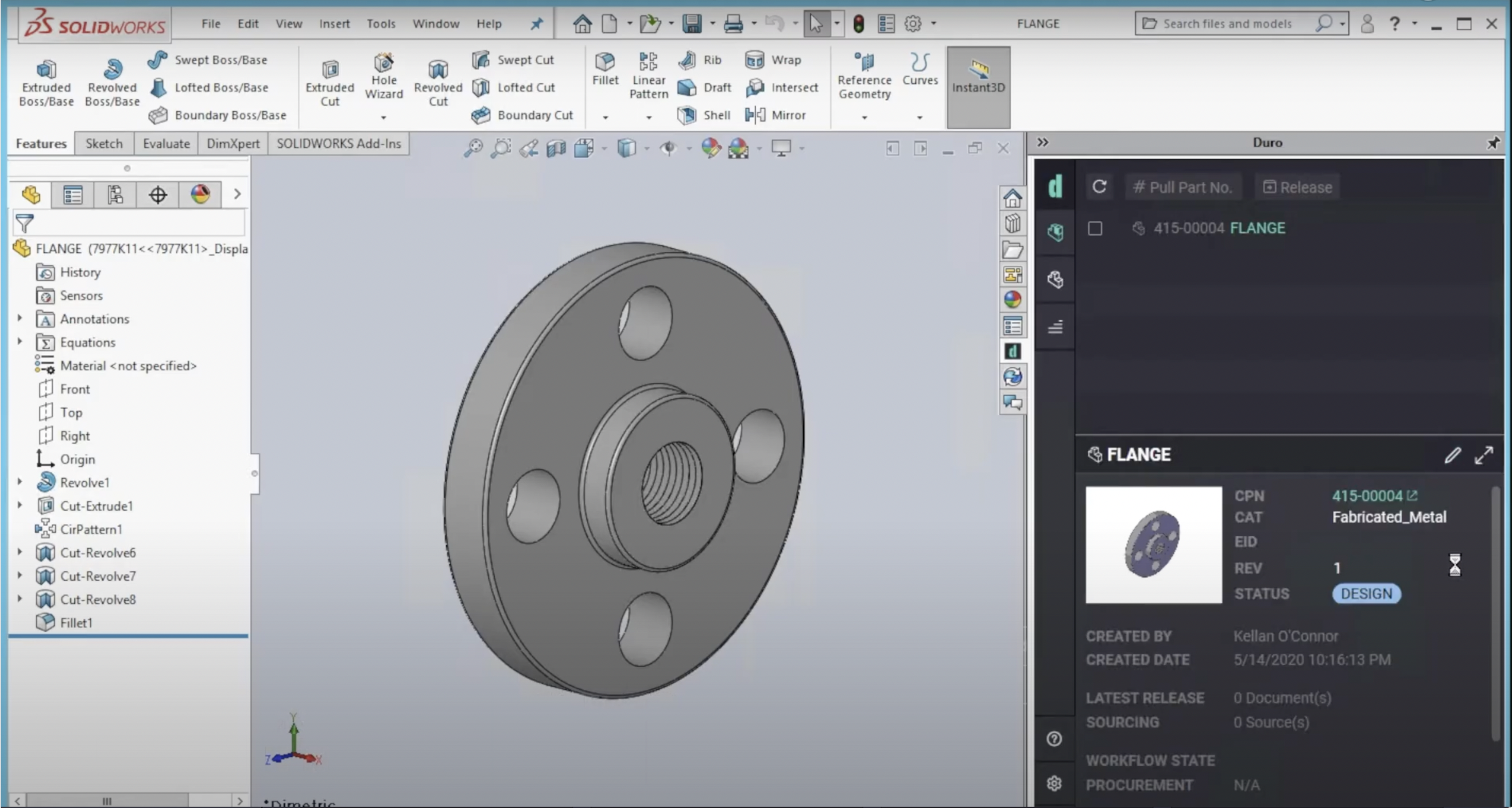

Beamlink needed a PLM solution that could integrate with their existing tools—SolidWorks and Altium—without disrupting their workflows. Arpad and the team were looking for a platform that was easy to onboard, user-friendly for those new to PLM, and adaptable to their existing processes.

“They don’t teach you about PLM in college. We wanted something easy to set up and learn,” he noted. This led Beamlink to Duro. “We didn’t have to change how we work,” Arpad said. “Duro supports all of our integrations like SolidWorks and Altium, and that flexibility was key for us. It made the decision easy.”

How Duro is Helping Beamlink Scale

With production runs underway and prototypes entering certification, Beamlink is progressing through commercial production with full FCC certification, using Duro to enhance efficiency. The team has seen instant, significant improvements in version control and collaboration.

“Having this PLM in place is already helping us track engineering changes, manage parts, and avoid costly mistakes with manufacturers,” Arpad noted. “With Duro, risks are now minimized. Everyone can find the information they need in the PLM without having to dig through emails or spreadsheets,” he added.

Beamlink aims to fully onboard all team members with Duro, ensuring that every product iteration and change order is meticulously tracked and easily accessible. This will be especially crucial as they advance through production, work with early customers in heavily regulated environments, and engage in discussions with large network carriers.

What’s Next for Beamlink?

Beamlink aims to cover its first major disaster in the next 12 months, impacting approximately 10.6 million people within three years. They already work with local partners who manage equipment and networks and have signed a landmark MOU with a telecom company in Nigeria. Beamlink has also established relationships with all four Hawaiian counties and most Pacific islands.

With Duro’s PLM, Beamlink is confident in its ability to scale while keeping everything in check. “Five years from now, if one of our Bentocells in the field has an issue, we’ll be able to trace everything back to the original design,” Arpad said. “That’s the future-proofing we needed, and Duro gives us that confidence.”

Beamlink isn’t just building hardware—they’re creating a new way to connect the world. With Duro as the foundation of their tech stack, they’re well on their way to connecting the next 3.5 billion people. Watch this space.