TABLE OF CONTENTS

Before Duro

After Duro

- Using disparate systems for CAD, ERP, and procedural documentation.

- Inefficiencies in product development with rising costs and risks of errors.

- Lengthy change order process requiring multiple reviews and approvals.

- Time-consuming management of part numbers, assemblies, and revisions.

- AstroForge had just 12 months to bring its space mining vehicle to market.

- Integrated existing tools into Duro PLM with instant Epsilon 3 access.

- Achieved a 20% improvement in time efficiency.

- Significantly reduced product development costs.

- Change orders approved in seconds with all documentation centralized.

- Accurate synchronization of all part numbers, assemblies, and BOMs.

- Space vehicle built ahead of schedule, raising $40M ahead of 2025 launch.

"As we grew, we had pain points and needed a PLM. Traditional PLMs were just too big and had a lot of overhead. We didn’t need a feature-heavy solution – we quickly onboarded Duro to get the capabilities we needed."

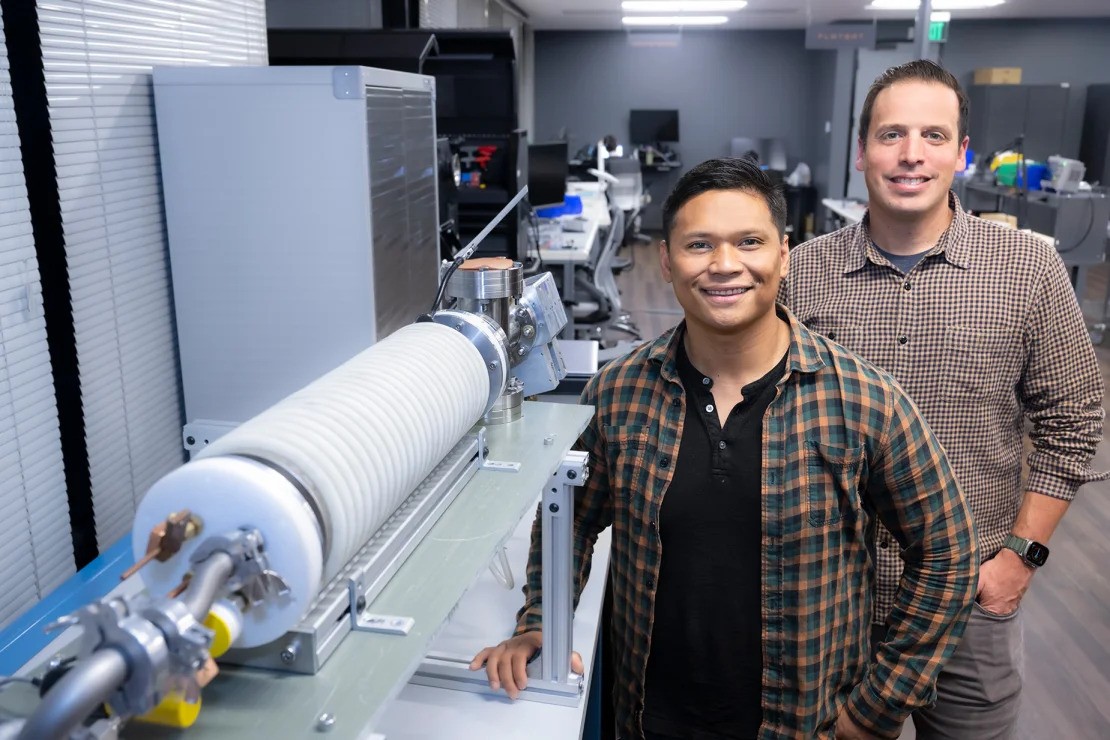

Jose Acain, Co-Founder & CTO, AstroForge

How AstroForge is Advancing Space Mining

AstroForge’s mission is to expand humanity’s ability to harness untapped space resources. AstroForge is redefining space mining by extracting critical metals from asteroids, making off-world resources accessible on Earth at a lower cost and with a smaller carbon footprint than traditional methods.

Challenges Before Implementation

AstroForge relied on disparate systems for CAD, ERP, and procedural documentation, leading to inefficiencies and a higher risk of errors. Managing part numbers, assemblies, and revisions was arduous, complicating data integration across platforms. Reviewing and approving change orders was heavily time-consuming. With just 12 months to launch, a PLM integrated with an operational procedures platform was needed to streamline product development and get to market on time.

Post Implementation Improvements

AstroForge saw a 20% improvement in time efficiency and reduced product development costs across the board. Using only essential tools from Duro’s tech stack, AstroForge reduced errors, streamlined communication, and accelerated workflows. Change orders were approved in seconds, freeing engineers for innovation and critical tasks. The integration ensured accurate syncing of all part numbers, assemblies, and BOMs, enhancing data accuracy with automated reconciliation.

"We can get a change order done within seconds, which is the greatest thing. The whole release process at Duro was a significant time saver. The approval process within the tool is excellent."

Jose Acain, Co-Founder & CTO, AstroForge

Why an Operations Procedure Platform was Important

Integrating Duro with Epsilon 3’s OPR platform was crucial in optimizing AstroForge’s operations. It helped standardize procedural documentation, testing, and operations. This integration enabled:

- Real-time data synchronization across both systems.

- Reduction of human error through automated reconciliation.

- Quick and easy transition from design to testing and operations.

"What’s great about Duro & Epsilon is the low cost and entry barriers. It just seemed like a perfect match for this integration to happen."

Jose Acain, Co-Founder & CTO, AstroForge

AstroForge Growth & Success

AstroForge’s growth trajectory has been impressive, marked by significant reductions in operational costs, improved data accuracy, and accelerated timelines. Duro’s role as the master source of truth for all product information has been crucial in ensuring sustainability and scalability, quickly positioning AstroForge at the forefront of the space mining industry–evident with its recent $40M funding, bringing the total raised to $55M.

While AstroForge continues to grow, challenges remain in maintaining supply chain predictability and enhancing real-time data synchronization. Duro continues to evolve its platform to meet these needs, empowering AstroForge’s engineers to make informed decisions through real-time data integration and predictive analytics, ensuring timely and cost-effective mission execution.

What's Next for AstroForge?

AstroForge will launch its next deep space mission in Q1 2025, utilizing Duro’s integration with Epsilon 3 to support the mission. With the new Odin spacecraft having passed vibration testing, AstroForge will use Duro to refine its current product based on the data gathered from this mission. By leveraging the PLM’s capabilities in the revision process, they aim to gain valuable insights for future improvements.

"With our upcoming mission, we're excited to use Duro and the Epsilon integration for our next design phase. Leveraging data to enhance and revise products, Duro will streamline our revision process to help gain valuable insights."

Jose Acain, Co-Founder & CTO, AstroForge