TABLE OF CONTENTS

PLM software systems enhance a company’s entire tech stack by centralizing design data and ensuring smooth communication between engineering, manufacturing, and procurement teams. By providing a single source of truth, PLM tools streamline workflows, reduce errors, and improve collaboration across departments.

When integrating Siemens NX with a PLM system, your PLM must include Product Data Management (PDM) capabilities. PDM ensures that design files are managed effectively, preventing overwrites and maintaining version control, which is critical for maintaining data integrity throughout product development.

It’s helpful to have an understanding of PDM vs. PLM when evaluating NX PLM software options.

What is Siemens NX?

Siemens NX (formerly Unigraphics) is a software suite for product design and manufacturing that features integrated CAD, CAM, and CAE solutions. Engineers rely on Siemens NX to design components and assemblies, which become part of the bill of materials (BOM). Integrating NX with the correct PLM system is essential for an efficient transition from design to production.

What to Look for When Screening a PLM for NX

Several key factors must be considered when searching for PLMs with PDM capabilities for NX. A robust PLM should allow for seamless out-of-the-box integration with NX and optimal performance for engineers. Here are the requirements to focus on:

CAD-PLM Integration

Select a PLM that integrates with CAD without requiring engineers to leave the CAD environment for PLM-related actions. PLM interfaces built natively into the CAD application can prevent productivity loss due to context switching, allowing engineers to maintain their workflow uninterrupted within the CAD tool.

Closed-Loop Release Process

Ensure that the CAD design release process, initiated within the CAD environment, integrates into a change order process managed within the PLM. The PLM solution should communicate with PDM systems for file access control, revisioning, and release workflows. This integration ensures ease of use with large, complex files and maintains data continuity throughout the product lifecycle.

Bi-Directional Metadata Exchange

The CAD-PLM integration must support the bi-directional exchange of metadata. Transferring part attributes like material, mass, and other critical data between CAD and PLM tools ensures data consistency and accuracy. This capability is essential for maintaining up-to-date and reliable information across all teams involved in product development.

PDM-CAD Integration

In conjunction with a PLM and NX, a PDM can enable hardware product design without the worry of overwriting work. Engineers can collaborate on design files without leaving the CAD application, ensuring complete control and ownership of intellectual property. Ideally, users should be able to directly leverage the full benefits of PDM and PLM within the CAD environment.

The 6 Best PLM Software for Siemens NX

Duro

Duro PLM integrates directly with NX CAD, enabling hardware engineering teams to release design revisions and production files to Duro’s centralized hub. Within the PLM, stakeholders can manage part numbers, transfer design data accurately, and maintain data continuity, ensuring real-time access to information and reducing errors. Duro’s PLM NX integration supports automated processes like creating mBOMs, managing change orders, streamlining workflows, and enhancing collaboration.

Design without distraction with PDM

Duro’s PDM One allows hardware product design work to be conducted without the worry of overwriting work. It enables collaboration on design files within the CAD application, ensuring complete control and ownership. PDM One utilizes best-in-class cloud storage and focuses on simplicity, security, and speed. Its simple setup process requires no IT resources or training, allowing engineers to start using it quickly. Data security is ensured through ITAR-compliant file storage platforms like Box, retaining control over CAD files.

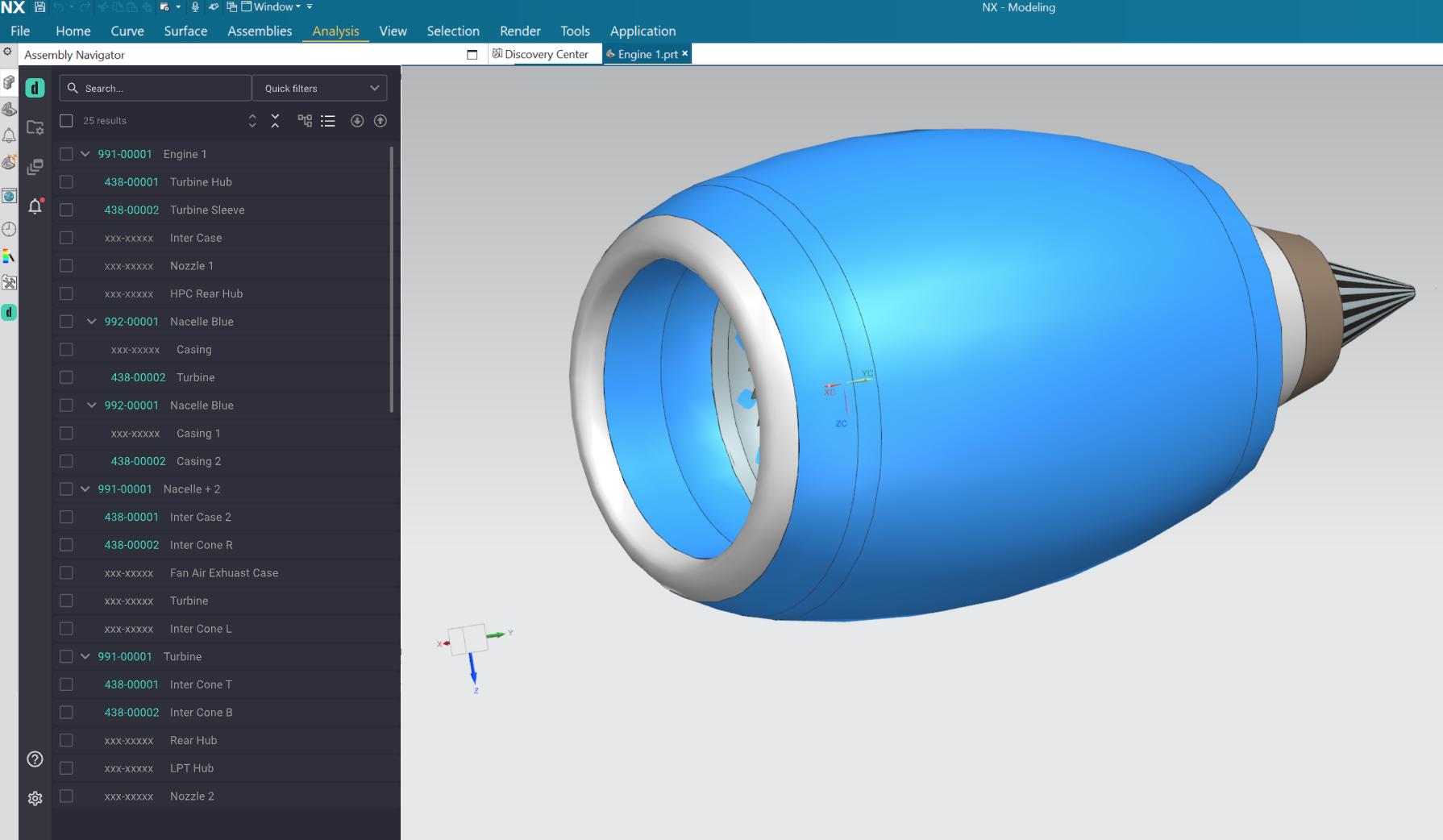

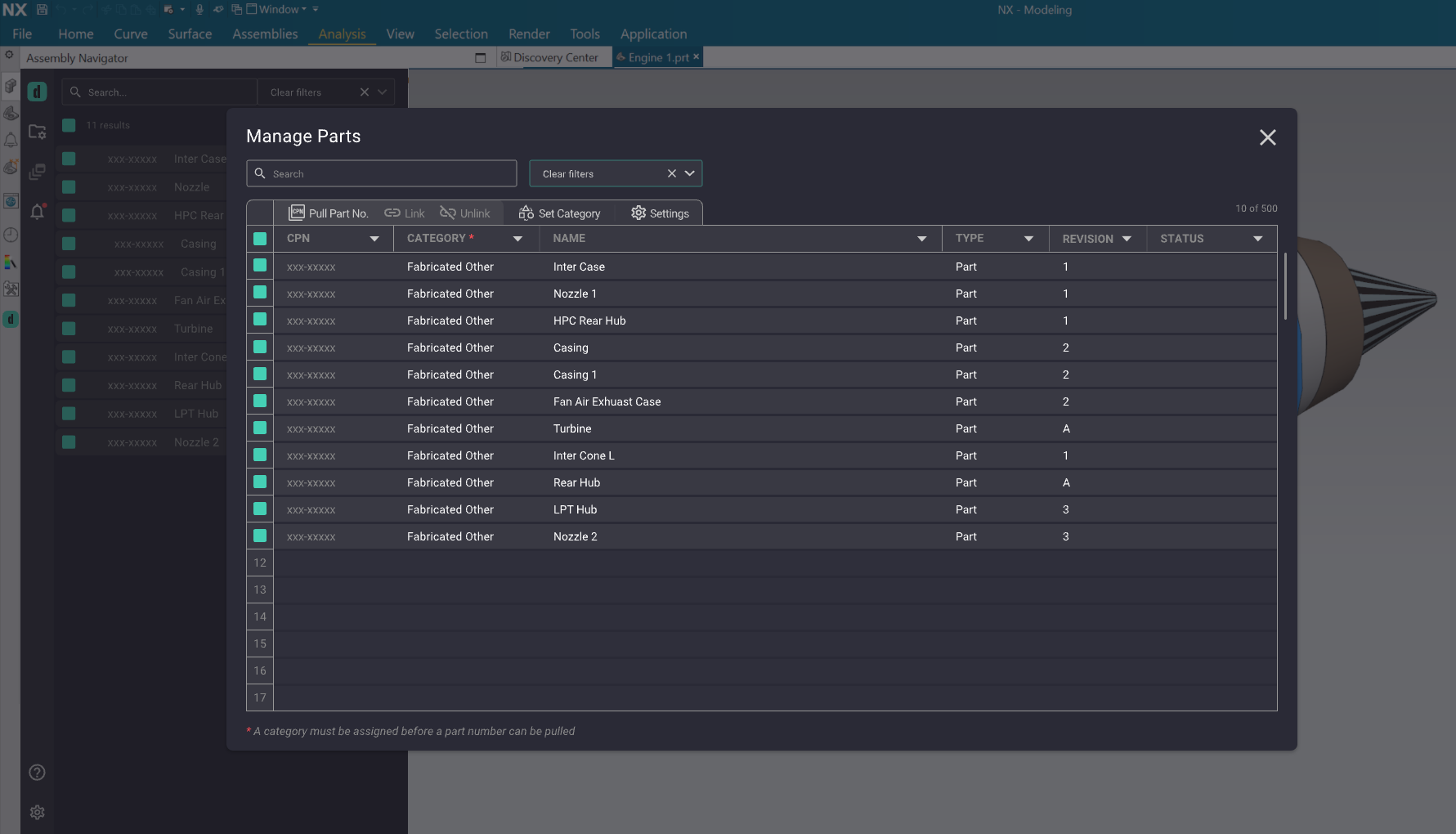

Duro built a unique NX Add-In

Duro’s latest PLM and NX mechanical CAD integration has reshaped engineering workflows, making new design releases effortless. The Duro NX Add-in allows users to manage part numbers, update product status, release files, and quickly find parts and assemblies. Siemens NX users can now integrate with the PLM tool of their choice rather than being locked into a single vendor. Duro’s native integration eliminates the need for third-party connectors, simplifies the process, and enhances efficiency with lightweight, agile workflows and a streamlined UI/UX.

Siemens Teamcenter

The Teamcenter integration with NX software reduces product development cycle times by enhancing the NX environment for design collaboration. It provides seamless management, control, and security for NX data. Teamcenter PLM users can search for designs and manage data revisions, product configurations, and changes in single—or multi-site deployments.

OpenBOM

OpenBOM supports various CAD, PDM, PLM, ERP, and CRM integrations. It is a global collaborative SaaS platform that manages data, the product development lifecycle, and production planning and connects manufacturers with their customers, contractors, and suppliers. OpenBOM can extract BOM, CAD, and neutral geometry files tailored to customer requirements.

PTC WindChill

PTC WindChill offers comprehensive capabilities that support the entire product lifecycle. WindChill’s software provides NX users with data management, version control, and collaboration tools, enabling seamless integration and efficient workflows.

ARAS

ARAS Innovator is a flexible solution for complex data management that offers integrations with NX. However, unlike Duro, ARAS relies on third-party connectors, which can complicate the integration process and add additional costs.

Enovia

ENOVIA offers users capabilities with integrations for Siemens NX. While it supports extensive customization, Enovia also relies on third-party connectors, which can lead to higher implementation costs and complexity compared to Duro’s native integration.

Why Duro PLM makes the most sense for NX users

Duro is the best-equipped PLM for NX due to its native integration, which eliminates the need for third-party connectors and simplifies the setup process. With roots in aerospace and defense, Duro understands the industry’s needs and provides a flexible, lightweight, and robust PLM solution, ideal for those who want an alternative to large, feature-heavy solutions like Siemens Teamcenter.

By choosing Duro, you benefit from a streamlined UI/UX, quick deployment, and efficient design data management. Duro’s PLM integration with NX empowers hardware teams to work more efficiently, ensuring data integrity and accelerating time to market.

In addition, you get the bonus of working directly with Duro and only Duro, avoiding the complications of third-party connectors or consultants.