TABLE OF CONTENTS

Ensuring collaboration and data accuracy across all stages of product development is crucial for hardware companies. Electrical engineers, mechanical engineers, supply chain managers, and manufacturers all require a centralized source of truth and the ability to connect their applications. This is where integrating Altium with a robust PLM system like Duro becomes indispensable.

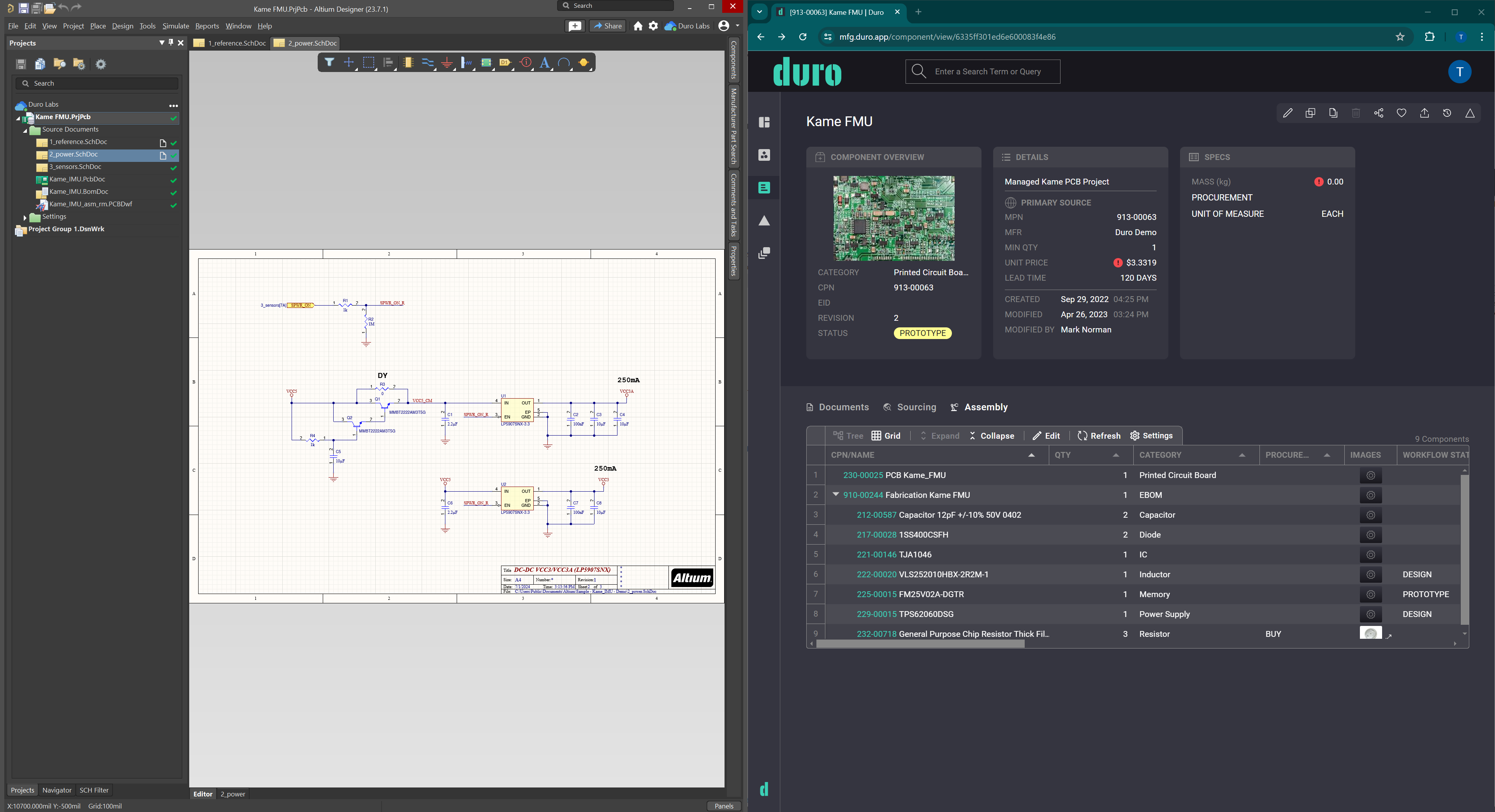

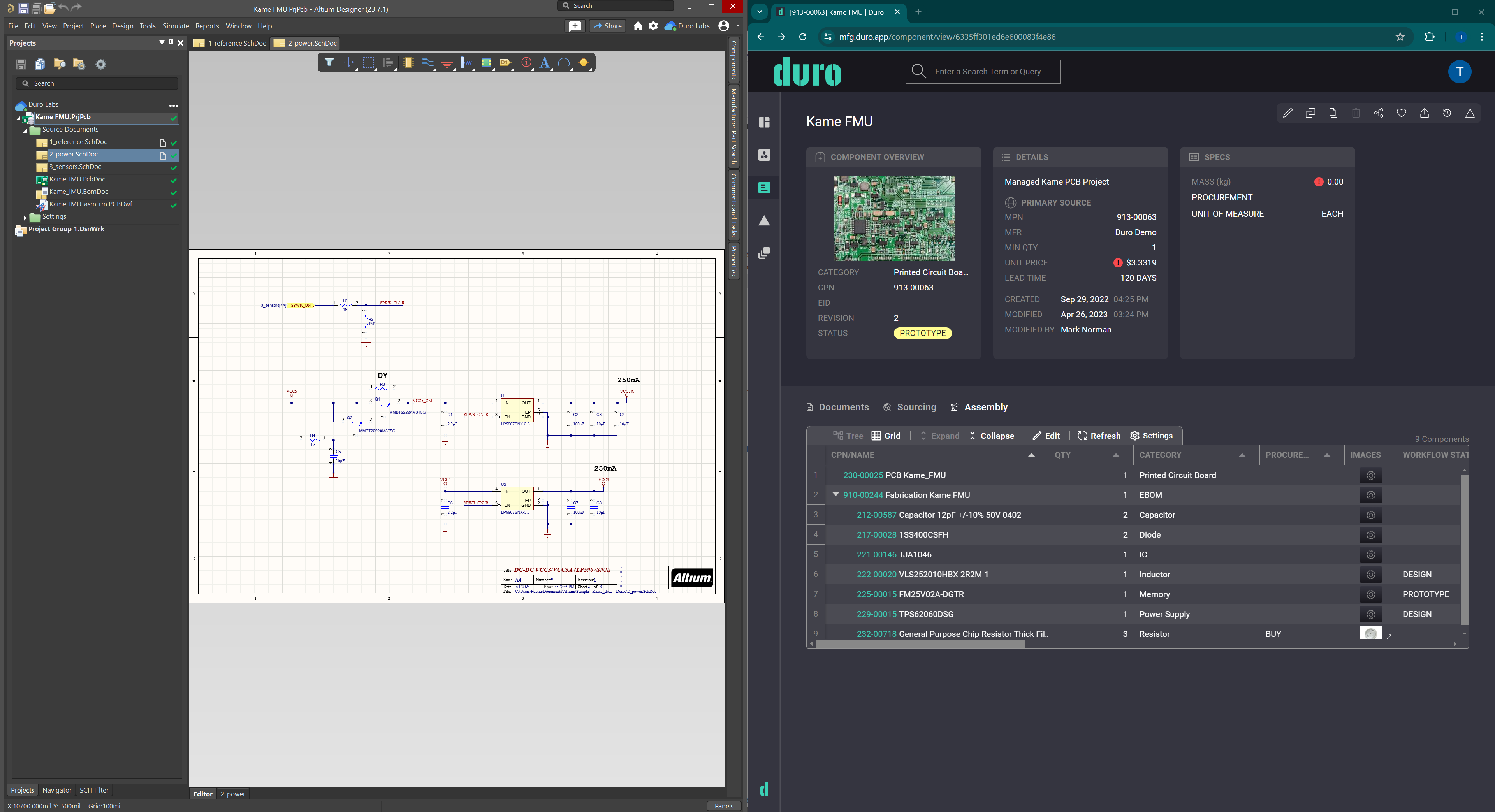

By connecting Altium to Duro PLM via the Altium 365 PLM Connector, teams can synchronize design data, streamline workflows, and maintain accurate, up-to-date information across the entire product lifecycle. This blog explains more about Duro’s integration with Altium Designer and its benefits. It also provides an Altium PLM tutorial on connecting the applications and synchronizing data.

Altium's role in hardware design

Altium is one of the leaders in ECAD software (electrical design). Its flagship product, Altium Designer, gives electrical and electronic engineers robust capabilities for PCB design, schematic capture, and layout design. Altium Designer includes extensive component libraries and design reuse capabilities alongside robust simulation and analysis tools that help engineers test and optimize their designs before production, reducing the likelihood of costly revisions.

When designing complex electromechanical products, such as small satellites, robotic arms, quantum computers, and energy management products, ECAD software like Altium is required alongside other hardware tools, such as mechanical CAD software and ERP platforms.

What is Altium 365?

Altium 365 is an electronics development platform that extends the capabilities of Altium Designer to the cloud. It enables remote teams to collaborate more effectively by removing data silos between applications. Schematic and PCB versions are stored in Altium 365 to facilitate version control.

Anyone with access can open and view them in the browser. The platform also incorporates a digital assistant to help with manual board assembly and the manufacturing portal to ensure you have the digital thread to collaborate with your manufacturer.

Altium 365 helps you integrate with other tools in the hardware development stack, such as requirements management or PLM. Additionally, it provides a centralized electronics components library with data like price availability, alternates, and manufacturing lifecycle statuses.

Why do I need an Altium PLM integration?

Many more stakeholders are involved in product development than electronic engineers and designers—product managers, procurement teams, software developers, mechanical engineering, manufacturers, and more all require centralized, accurate information. To truly create exceptional products efficiently, these teams must work together. Without an integration, hardware teams can face issues with:

- Increased errors and rework: Reliance on manual processes for data sharing between ECAD software and PLM tools, such as design data, BOMs, and PCB schematics, can lead to inaccuracies. Missing or mistyping data can lead to downstream issues in manufacturing.

- Workflow Disruption: Engineers must leave their familiar ECAD software tools to set up projects or transfer information to a different environment. Not only does this involve manual data upload and part number creation, but it also requires disrupting work to switch applications, adding unnecessary time to the design process.

- Inability to track changes: Lack of traceability for post-design processes or modifications to a design can lead to difficulty finding and managing parts later. Without the ability to centralize data across mechanical, electrical, and firmware, there’ll be bottlenecks as engineers waste time searching for parts or struggle with version control.

- Poor collaboration: Team members who don’t have access to Altium won’t be up to date with the latest files. Without the right information, there’s a risk that procurement managers order the wrong components or manufacturers start working on an out-of-date design. These errors can be costly.

Integrating Altium Designer with your PLM system facilitates communication and cooperation with the project’s stakeholders.

The benefits of connecting Duro PLM with Altium

Duro and Altium want to enable hardware designers to create great products. When integrated, Altium 365 and Duro can significantly improve the efficiency and effectiveness of design and production processes. Integrating the two tools ensures all stakeholders have access to the most up-to-date information, reducing errors and accelerating time-to-market.

The integration is simple to set up with Altium’s PLM Connector, which acts as a bridge connecting the two systems. Easily synchronize schematics, PCB designs, sourcing, manufacturing data, and components for easy data management and collaboration.

Engineers can quickly transfer project information and update revisions in their PLM for review by other team members. Automatically generate an eBOM from Altium to Duro, pull part choices into Duro sourcing, and create releases and change orders within Duro. Plus, bi-directional data synchronization between Altium 365 and Duro ensures you can push data from Altium to Duro and vice versa.

Duro Altium integration advantages

- Reduce context switching: Ensure consistency by quickly pushing all relevant information to Duro within the familiar Altium interface.

- Faster workflows: Without an integration, managing data flow between ECAD software and PLM involves a lot of manual effort. Engineers must enter component data in both systems, leading to errors and wasted time. The integration means electrical engineers can quickly share data between the two platforms. Pre-existing templates in Altium help to standardize and define project parameters.

- Accurate data across every tool: The bi-directional data exchange automatically synchronizes parts metadata and releases files between Altium and Duro PLM in both directions. You can customize the synchronization schedule to fit your specific workflow needs, ensuring data remains accurate and consistent.

- Automatically generate part numbers. When you create a project in Altium, you have the flexibility to manage parts in either system. Choose whether to create new parts and part numbers within Altium or Duro. Updates are reflected in both platforms, creating a unified library that caters to your preferences.

- Search experience: Bidirectional sync means that engineers can search for all available parts directly within Altium or Duro, regardless of where the part was initially created. There’s no need to switch between systems or waste valuable time searching for parts.

- Connect design and manufacturing: Once the design is complete, accurate data needs to be shared with procurement and manufacturing. Pre-configured output templates are available in Altium. Then, with a single click, publish all relevant project data to Duro PLM to share downstream with manufacturers and supply chain partners.

In summary, the integration saves time, minimizes errors, and ensures everyone has a consistent view of the project components in both Altium, 365, and Duro PLM. Engineers and designers can focus on innovative design work within the native ECAD environment without continually switching back and forth to their PLM tool to share information with other team members.

Which data can you transfer between Altium and Duro?

- Reusable ECAD Data: Includes predesigned and configurable elements that can be reused across multiple projects, saving time and effort.

- Product Releases: Facilitate accurate data transfer to manufacturing, including production files for the PCBA, such as Gerber files, NC drill files, ODB++ files, and pick-and-place files. Additional details like part numbers, revision history, version history, and any supplier/vendor details can also be transferred to ensure accuracy and consistency.

- Source Data: Encompasses original design files, including schematics and PCB layouts, which are crucial for design integrity. Important attributes like mass, material properties, and detailed descriptions are also included.

- Components: The essential building blocks of your designs, including key information like part numbers, material properties, and supplier/vendor details, ensure comprehensive data management across the project lifecycle.

PLM Altium Tutorial

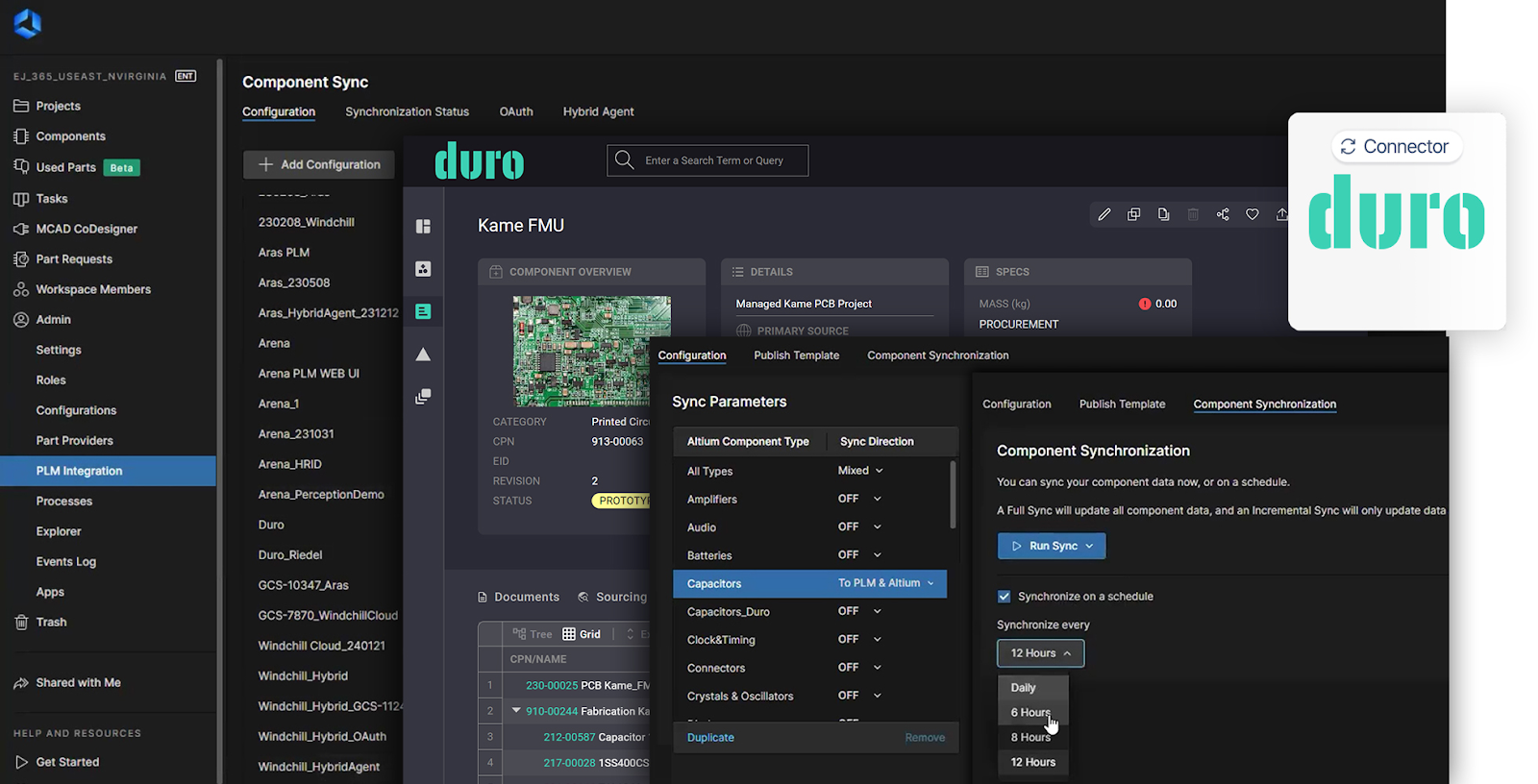

After configuring your Duro PLM instance with Altium 365 by mapping parameters and selecting which direction to push the data, you can synchronize your Altium library and projects with Duro. Watch a free PLM Altium Tutorial here.

Synchronizing components between Altium & Duro PLM

Let’s say you have a set of components, such as capacitors, in Altium, and you want to synchronize those with Duro.

- Map PLM parameter names with the Altium parameter names in the Altium 365 settings. You can use a predetermined configuration out of the box if you don’t want to customize these settings. Map the name and part choices. For example, ‘CPN’ in Duro matches ‘Altium Parameter Name.’

- Choose whether to synchronize data manually on demand or on a schedule, such as once a day. Synchronizing on a schedule makes sure that this process happens regularly and automatically.

- Once synchronization is complete, you’ll find your components in Duro. The capacitance, MPN, and manufacturer are all available in Duro, alongside part choices and different options for buying the component. With bidirectionality, Duro components will also be created in Altium.

Creating a project

To create a project in Altium and ensure the project is set up at the same time in Duro PLM with matching numbers, you can run the process in Altium 365 or directly from Altium Designer.

- In Altium Designer, create a new project. Add a name and description and choose a template for that project.

- Provide credentials to the PLM instance so the project will also be created in Duro.

- When the project is created in Duro, the values are written to Altium 365. Clicking the refresh button in the project options pulls these values from Altium 365 to update them in Altium Designer.

- The project has now been created in both Altium and Duro PLM with all the product numbers that were provided to Altium.

Releasing a project

- To release a project into Duro, you’ll use the project releaser within Altium Designer.

- Create the items, commit, and publish them to PLM. You can also modify those using the workflows in Altium Designer.

- All the data is prepared in Altium Designer to perform the release, including the bill of materials.

- You’ll provide credentials to the Duro instance, and then the data is transferred directly.

- Assembly data for the fabrication, Gerber files, and any related documents have been transferred to Duro.

Watch how to quickly publish a release.

How to access the PLM connector

There’s no need for a third party or additional software to connect the two applications. Altium’s 365 PLM Connector is an out-of-the-box PLM integration with configurable process workflows to easily synchronize your projects, parts, sourcing, and manufacturing data with Duro PLM. You only need the PLM Connector to be enabled within Altium 365. You’ll set up and configure the integration through the web-based user interface within Altium 365. Processes are incorporated into Altium Designer.

Connect your tech stack with Duro today

Duro works with leading hardware companies to build an entire technical data management stack. This tech stack spans from CAD tools and requirements management to production and manufacturing tools like ERP or MES. A simple stack could be composed of Altium 365 and SolidWorks, merging that data into Duro PLM and then delivering that to an ERP like NetSuite.

The Altium 365 to Duro PLM integration is essential to improve design workflows. It eliminates the need for manual data entry between design software and PLM and ensures every team has access to the latest information. This translates to significant time savings and reduced errors for your design team. Chat to our team today to access the integration or see a demo.