TABLE OF CONTENTS

Before Duro

After Duro

- Struggled using Microsoft SharePoint to manage documentation.

- Gilmour’s team had no change control process.

- Engineers were unable to find the latest revision.

- Next to impossible to track changes in designs.

- No option for engineers to return to a previous baseline when needed.

- Engineers could reliably predict and follow production timelines.

- Track changes and surface data for regulators for launch permission.

- Copy-paste functionality for rocket designs, speeding up iteration processes.

- Raised $36M in series D and launching three-stage rocket in 2025.

“Without being able to define a baseline or manage changes to our products in Duro, we wouldn’t have the confidence in our design to be able to seek launch permission.” – Senior Launch Vehicle Engineer, Gilmour Space

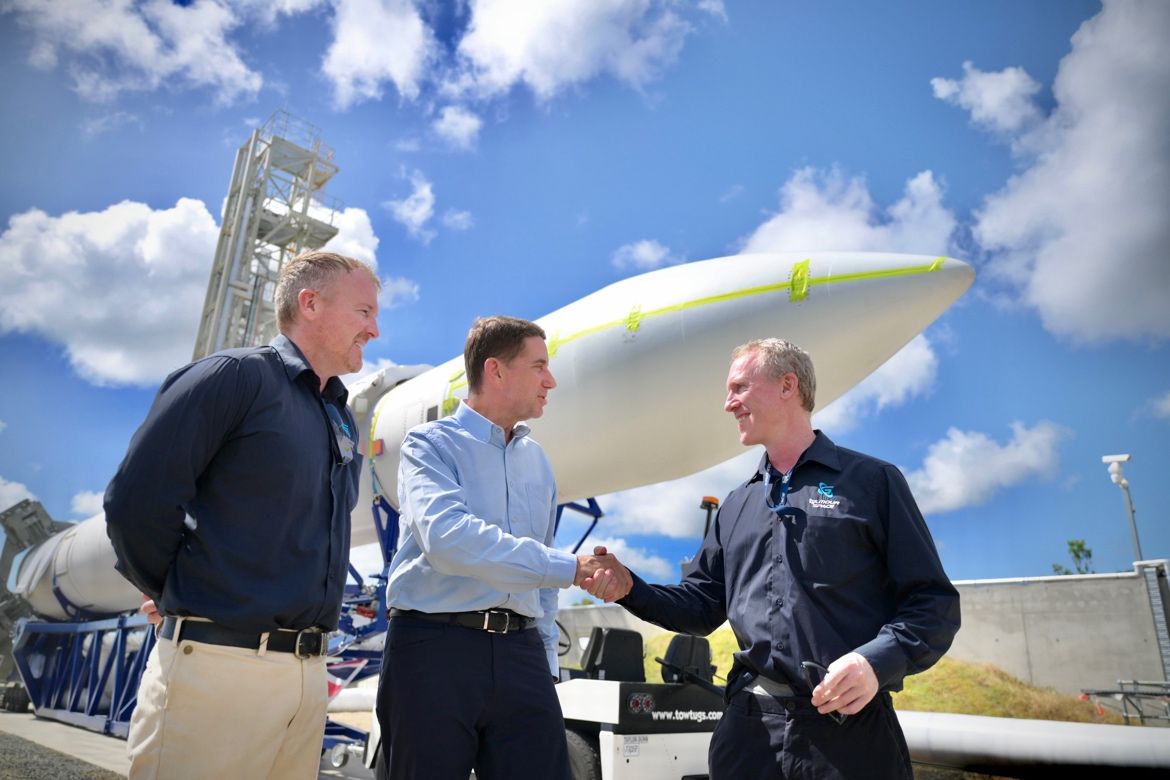

Introducing Gilmour Space

Gilmour Space Technologies is a leading Australian-owned aerospace company specializing in LEO launch vehicles, hybrid rockets, and small satellite platforms. Since launching its rocket program in 2015, Gilmour has advanced hybrid propulsion technologies to provide cost-effective access to space. Gilmour Space offers mission management, launch services, and satellite buses to support the growing demand for small satellites and commercial space operations.

Gilmour Space's Challenges

As Gilmour’s team expanded, configuration management became a major challenge. Engineers relied on Microsoft SharePoint for document management but struggled to access the latest designs, often downloading and emailing files across different tools. No structured change control process made it difficult to track changes, retrieve past designs, or revert to previous baselines. Gilmour needed a flexible solution to manage design revisions and change control efficiently while ensuring cost-effectiveness and integrations with internal and third-party tools.

How Duro's PLM Helped

Gilmour implemented Duro to enhance its design and change management processes, integrating it with their CAD, MES, and Requirements Management tools for increased transparency across the product lifecycle. Engineers gained daily access to Duro to track design revisions, upload components, and manage documentation.

Single Source of Truth for Product Data

Duro centralizes bills of materials, parts, and assemblies across all engineering teams. Real-time access, weekly change reviews, and full traceability between launch vehicle versions ensure smooth approvals, revisions, and regulatory compliance for launch.

Promote and Release Designs via CAD Integrations

Gilmour engineers can sync and release SolidWorks and Onshape designs into Duro, tracking bill of materials and component changes. New data auto-populates from CAD, and approved revisions update instantly.

Improved Product Development Processes

Gilmour can track production timelines, accelerate iteration by copying rocket designs, and simulate design impacts using Duro’s data. Engineers optimize designs with sourcing data on mass, price, and availability, while high-fidelity modeling catches issues early and maximizes benefits.

Share Design Data with Manufacturing Teams

Gilmour integrated Duro with First Resonance’s Factory Operating System – ION, enabling automatic part duplication and validation every six hours. Changes in Duro instantly update order details in ION, allowing the manufacturing team to plan and schedule work efficiently.

Gilmour Space Growth & Success

In 2024, Gilmour Space raised $36 million in Series D, keeping it on course for several launches and becoming the first Australian-built rocket to enter orbit. After marking a significant milestone with the opening of its Orbital Space Port Base, Gilmour began testing its three-stage rocket, “Eris” in early 2024. A second test flight later in the year followed. Gilmour Space’s historic commercial launches are set to begin in 2025.