TABLE OF CONTENTS

By 2030, the global manufacturing industry is projected to generate 4.4 zettabytes of data—a massive volume that requires advanced metadata strategies to remain manageable and useful. Properly leveraging this data will determine manufacturing companies’ ability to stay competitive in the new era of massive data streams.

Metadata, often described as ‘data about data,‘ gives raw information meaning—making it easier to find, organize, and use. Yet, in manufacturing, where complex supply chains and outdated systems are the norm, metadata is often overlooked or underutilized.

This article will explain five key ways AI can enrich metadata, help manufacturers drive innovation, and accelerate time to market. We will also look at the benefits of pairing AI-enriched metadata with agile PLM (product lifecycle management) software.

What is Metadata & Metadata Enrichment?”

Metadata provides the “who,” “what,” “where,” and “why” of data, giving structure and meaning to raw information. Using this information, metadata enrichment is a process that refines technical data into contextually meaningful assets, describing roles, formats, and relationships to improve usability and accessibility.

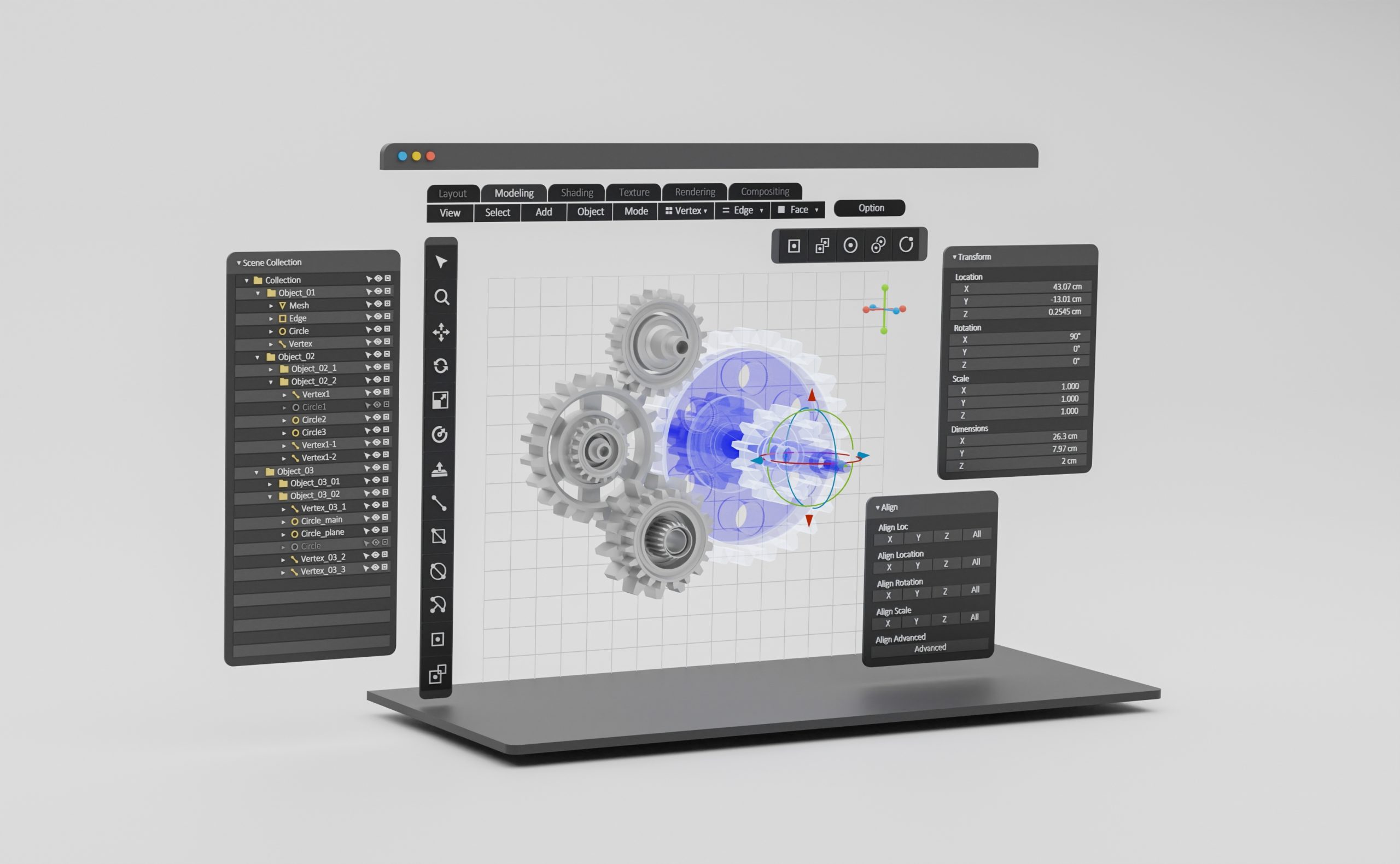

In the manufacturing industry, metadata enrichment ensures that everything from CAD files to scanned documents and assembly line logs can be efficiently located, interpreted, and used. It refines data by adding details like tags and keywords that make it easier to find, analyze, and use effectively.

AI is crucial in automating this process, reducing manual effort while ensuring consistency, accuracy, and depth. AI can analyze a CAD file and automatically extract part dimensions, materials, and compliance standards.

AI makes it easier for engineering and procurement teams to quickly find and apply relevant data. AI-powered metadata enrichment allows organizations to unify large amounts of data, bridge engineering, and business silos, and make data-driven decisions at every stage of design, production, and operations.

Manufacturing Data Challenges

Manufacturing data is uniquely difficult to manage due to its complexity and deep integration with technical processes. Unlike standard business data, it often includes intricate engineering drawings, CAD models, scanned legacy documents with handwritten annotations, and unstructured data from IoT sensors and supply chains.

AI-powered solutions help address these challenges by automating metadata enrichment at scale, ensuring consistency across disparate sources, and uncovering insights from previously buried, unstructured formats.

Ongoing supply chain disruptions don’t make data management any easier. Nine in ten manufacturers reported disruptions in 2024, reinforcing the need for more adaptive, AI-driven data solutions. As global supply chains grow more complex, manufacturers are turning to AI to manage and utilize their data, ensuring greater efficiency, accuracy, and resilience.

How AI Enriches Metadata in Manufacturing

High-quality metadata is crucial for searching, retrieving, and analyzing data, but manual curation is inefficient, given the volume of data generated by manufacturing processes. AI-powered tools can help companies overcome these limitations and efficiently enrich their metadata. Here’s five ways it achieves this:

1 - Improved Context and Discoverability

AI can convert complex technical information into formats that are easier to interpret. By scanning a bill of materials (BOM), AI can rename fields labeled “PLN_END_DT” to “Planned End Date,” allowing team members to track and manage key deadlines. AI links these standardized data points to related information such as project milestones, company timelines, and supply chain details.

AI-enhanced metadata makes data more searchable by extracting keywords and generating related terms. AI can process a CAD file and produce associated terms like “assembly design” or “load capacity,” making the file easier to find. AI can proactively suggest required components, maintenance schedules, or deadlines related to the file being searched for.

2 - Legacy System Integration

AI bridges the gap between legacy systems and modern data strategies, turning outdated paperwork, drawings, and production logs into digital, searchable assets.

Advanced Optical Character Recognition (OCR) trained on engineering symbols (e.g., GD&T symbols) can extract actionable data from technical documentation, blueprints, and scanned records. AI can quickly analyze engineering diagrams, extracting geometric tolerances and part specifications for quick and easy integration into modern workflows.

With AI enhancing systems like agile PLM (product lifecycle management) software and making decades of physical records digitally accessible, manufacturers can ensure that no critical data is lost in translation.

3 - Automated Metadata Validation

Bad metadata slows everything down—files get lost, parts are mislabeled, and mistakes slip through the cracks. AI can fix this by automatically checking metadata for missing details, outdated information, and errors before they cause real problems.

If an engineer forgets to add a material spec to a CAD file, AI immediately flags the issue, preventing costly delays or errors during production. AI can also cross-check part numbers, compliance details, and supplier data to ensure accuracy before they move to procurement or manufacturing.

4 - Predictive Maintenance and Operational Efficiency

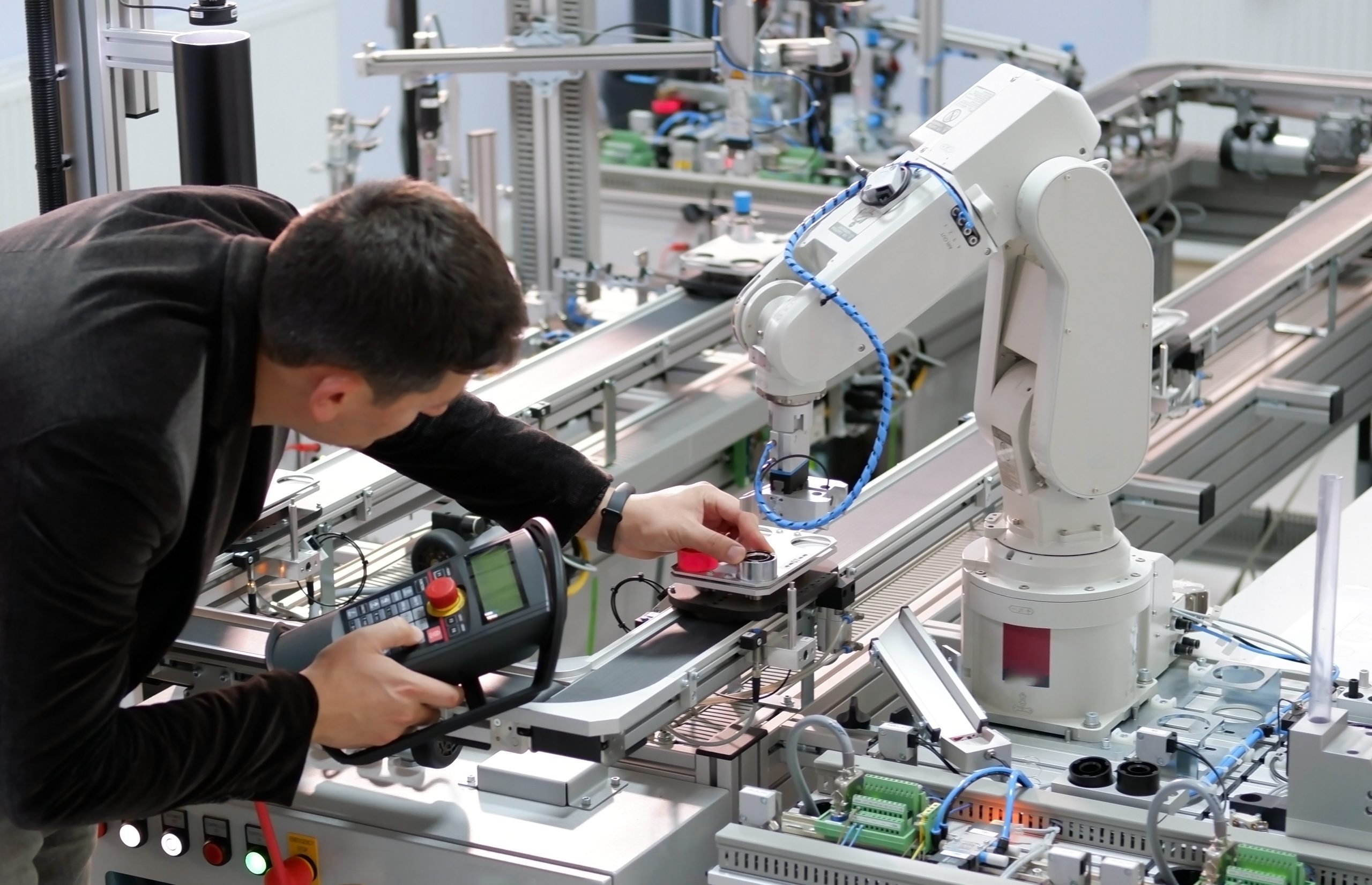

Metadata is crucial for predictive maintenance and factory operations. By analyzing data from IoT sensors and machine logs, AI can catch small performance issues before they turn into bigger problems, allowing teams to fix equipment before it fails. That means fewer breakdowns and longer lifespans for machinery.

But maintenance is just one part of the process. Metadata also helps manufacturers track energy consumption, which can reveal inefficiencies and underused equipment. Manufacturing companies can use these insights to fine-tune production and reduce waste.

5 - Assembly Line Insights

AI-driven metadata tracking helps manufacturers pinpoint bottlenecks, fine-tune production flow, and get real-time alerts when performance deviates from the norm. If setup delays or material shortages are slowing things down, AI can flag these issues before they escalate, allowing managers to take quick action.

Metadata makes it easier to track key production metrics—like cycle times and throughput—helping teams spot inefficiencies and optimize workflows. With real-time data analysis, manufacturers can make on-the-fly adjustments to keep operations running at peak efficiency.

Why AI is key for Manufacturing Data Management

Managing vast amounts of manufacturing data is a growing challenge, and outdated systems make it even harder for companies to stay efficient. AI-powered metadata tools help organize and enrich data, allowing teams to work smarter, reduce costs, and make faster, more informed decisions.

The impact is even greater when AI-enriched metadata is combined with an AI-enabled PLM system. These advancements create a centralized hub for product and supply chain data, giving teams real-time insights to drive efficiency, foster innovation, and accelerate time to market.

As supply chains grow more complex and production demands rise, the sheer volume of unstructured data makes AI-driven metadata essential. Companies that embrace the benefits of AI in supply chain management will gain a competitive edge, while those that hesitate risk falling behind in an industry where data-driven efficiency is no longer optional.