TABLE OF CONTENTS

The global PDM (Product Data Management) software market was valued at $2.53 billion in 2023 and is expected to nearly double to $5.23 billion by 2031, growing at a compound annual growth rate (CAGR) of 10.9%. This growth highlights the appeal of PDM software for engineering teams aiming to streamline product development and enhance collaboration.

We’ve seen this firsthand when new and existing customers ask about embedding PDM within their PLM systems to better manage data. This isn’t surprising, as it reflects the growing need for efficient workflows and data centralization in modern engineering.

The big question: Is your tech stack missing a component that could enhance your product development workflow? Here, we look at why PDM software is key to managing data, how it works and differs from PLM (Product Lifecycle Management), and why pairing it with a flexible PLM system can supercharge your operations.

What is PDM Software?

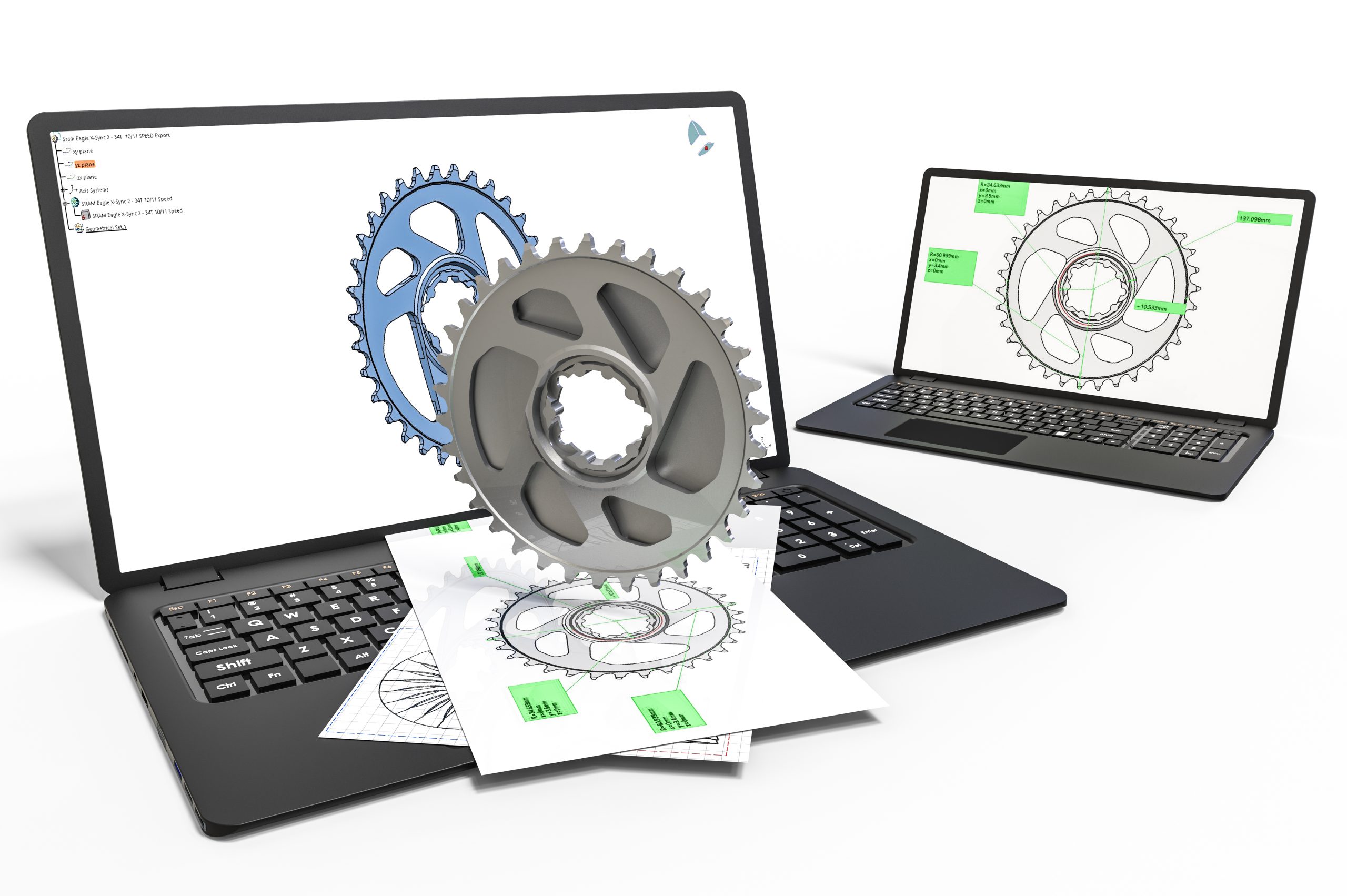

PDM software centralizes and protects design and engineering data, making it essential for teams relying on CAD tools to develop hardware products. As teams scale, managing CAD files, version histories, and configurations manually becomes increasingly complex, leading to wasted time, duplicated work, or lost data.

In a CAD-heavy environment, a co-located CAD PDM system is essential. It ensures that all design files—from early concepts to final production models—are stored securely and easily accessible. With the right PDM software in place, teams can:

• Centralize Data: Consolidate all product information into one secure repository.

• Maintain Version Control: Prevent overwrites and track every revision.

• Enhance Collaboration: Enable seamless sharing of accurate data across teams and collaborators.

While small teams may manage without PDM, scaling demands a more structured approach. Combined with a PLM system, PDM ensures design data integrates smoothly into the broader product lifecycle, improving efficiency and collaboration.

What's the Difference between PDM and PLM?

PDM and PLM are complementary systems that often work together but serve distinct roles. As companies advance through the product development lifecycle, they generate vast amounts of data—from design sketches and CAD files to quality testing results and customer feedback.

Managing this data is essential to overseeing the entire product lifecycle. Companies adopt PDM and PLM systems to handle this complexity, which makes it important to have a good PLM strategy connected with PDM. Here’s how they differ:

•PDM: Manages CAD files and revisions within engineering teams, enabling efficient collaboration and document control.

•PLM: Oversees the entire product lifecycle, from concept to retirement, integrating data across engineering, manufacturing, procurement, and other departments.

Does PDM or PLM come first?

For growing companies, PDM usually comes first as the need to manage growing CAD data becomes critical. PLM adoption often follows or occurs simultaneously, adding broader visibility and connecting stakeholders across the organization. The best solutions combine PDM and PLM functionalities, offering an alternative to standalone systems like SolidWorks PDM.

Why Your Tech Stack Needs PDM

The hardware industry demands a tech stack facilitating rapid product development and smooth collaboration. Modern engineers need flexible and agile tools to efficiently handle sourcing, bills of materials (BOMs), change orders, and revision control. When combined with a PLM strategy, PDM software creates a comprehensive hardware data management stack optimized for evolving needs.

Benefits of Using PDM Software

PDM significantly enhances how teams work by centralizing data, improving collaboration, and reducing errors. These improvements make day-to-day tasks more efficient while laying the foundation for better cross-departmental collaboration. The benefits include:

- Centralized Data and Version Control: Consolidates CAD files and ensures consistent, up-to-date project data.

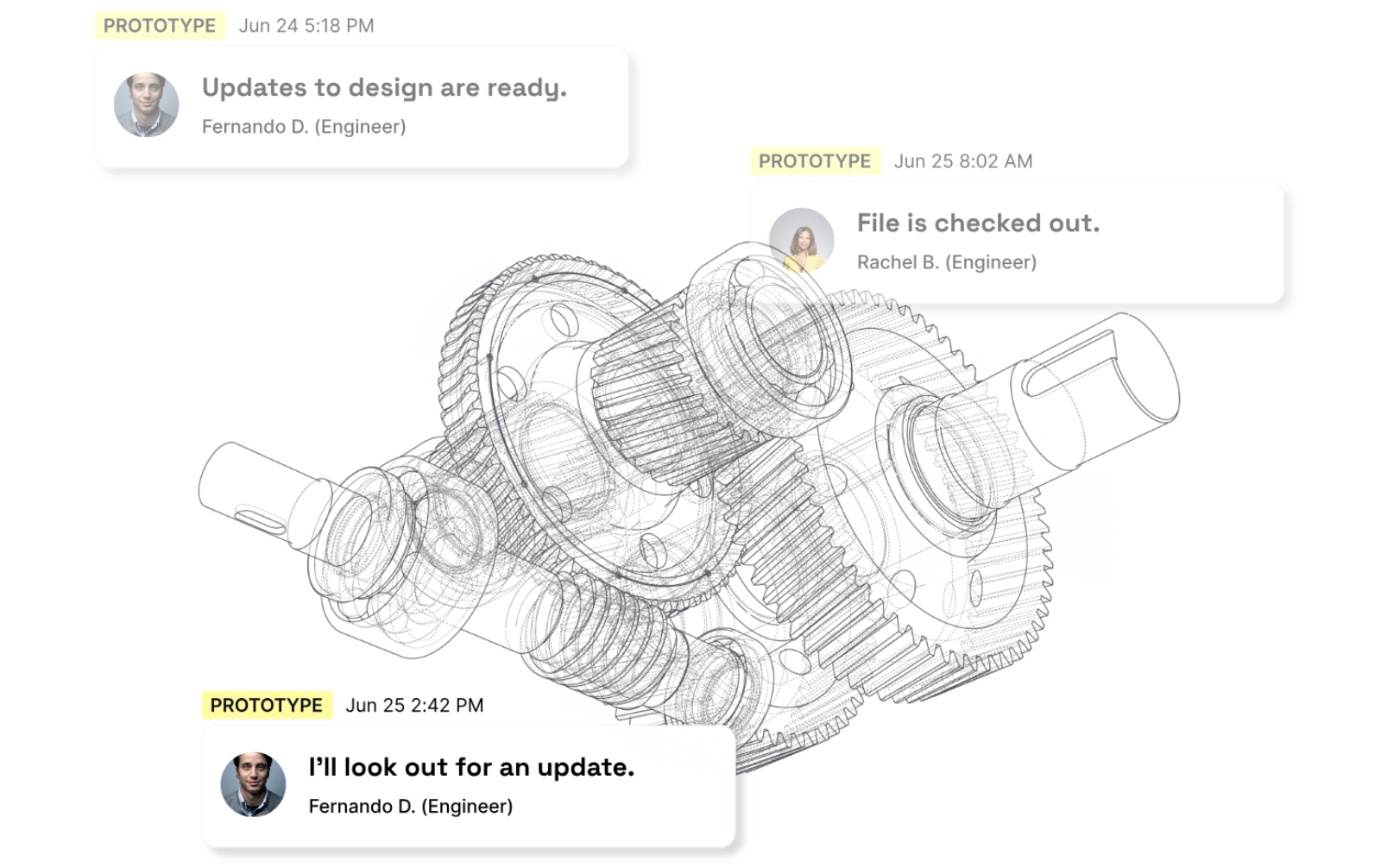

- Improved Collaboration: Real-time access allows seamless teamwork and reduces miscommunication.

- Enhanced Productivity and Security: Engineers spend more time designing with structured workflows and secure access controls that protect intellectual property.

What to look for in PDM Software

CAD Integration

A good PDM system must integrate with your CAD tools, allowing engineers to manage files directly within their design applications. For organizations that use multiple CAD platforms, selecting a PDM solution with robust multi-CAD support is essential, ensuring flexibility and scalability as your teams grow.

Workflow Enhancement

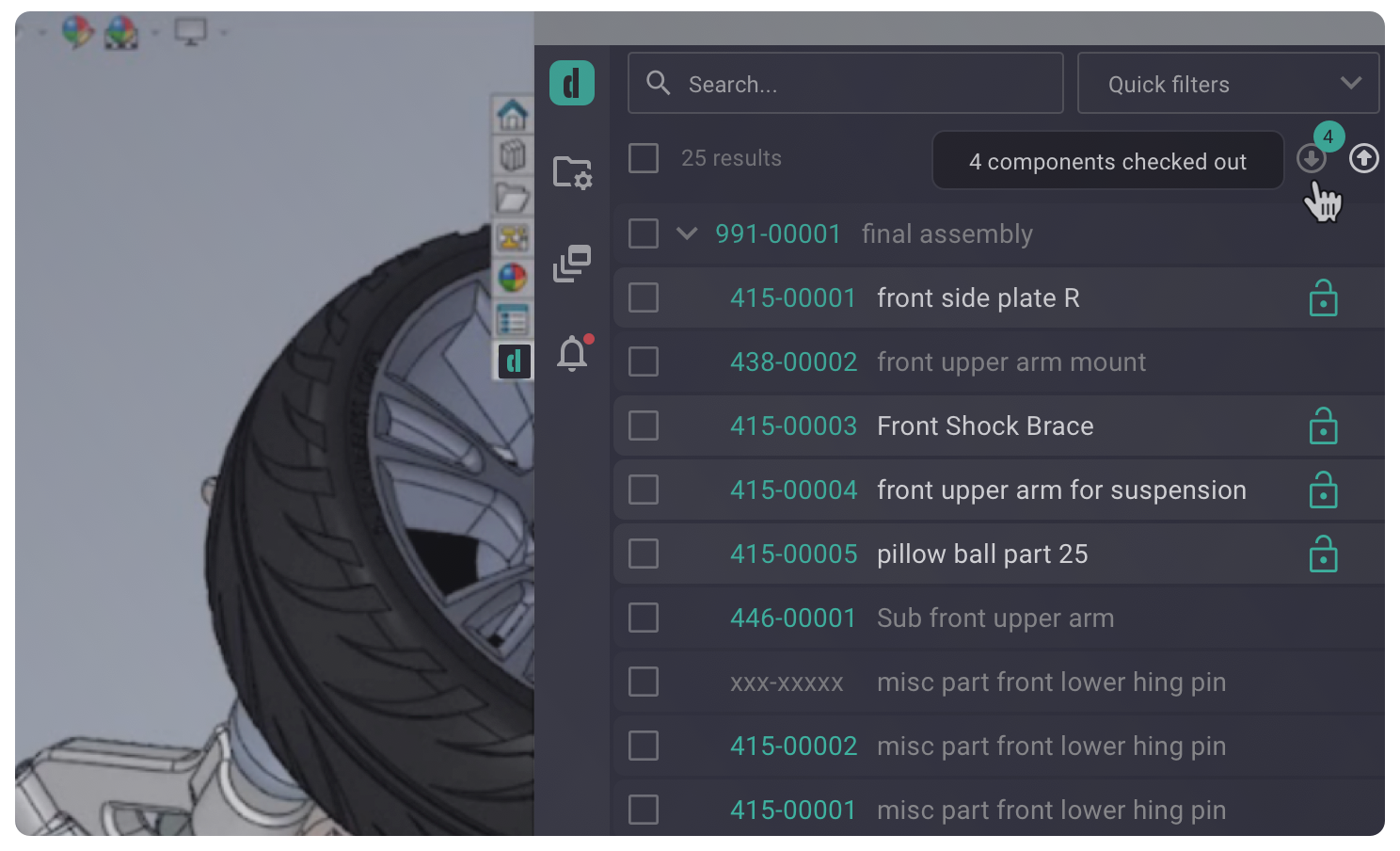

PDM systems should be straightforward to use, fitting easily into an engineering team’s established workflows. Key features like check-in/check-out and file-locking ensure engineers can securely manage their data without interrupting their design process or switching between tools

ITAR Compliance

ITAR compliance is a critical requirement for industries like aerospace and defense. The right PDM system should work with ITAR-compliant file storage platforms, providing the necessary security measures to protect sensitive data and intellectual property while adhering to U.S. government regulations. To see how to build an ITAR-compliant tech stack, check out our guide.

Affordability

Cloud-based PDM solutions offer significant cost advantages over traditional systems by reducing upfront expenses and eliminating the need for extensive IT resources and the need to be on-prem. These systems should come ready to use with minimal setup, allowing teams to quickly adopt the tools without lengthy training or additional infrastructure costs.

PLM Compatibility

A PDM system is most effective when integrated with a flexible PLM platform. This combination ensures a simple flow of data across the product lifecycle, enhancing collaboration between departments, reducing errors, and accelerating time to market. By connecting design data to broader lifecycle management, organizations can improve overall efficiency and decision-making.

Start Strong: Choosing the Right PDM Software

Selecting the right PDM from the beginning helps manage your design data effectively, especially when combined with an effective PLM strategy. A well-integrated PDM and PLM system ensures that your product development processes are agile, scalable, and future-proof. Traditional systems lack flexibility, while CAD-native solutions like Duro PDM One give you the tools to manage data efficiently while scaling up as your needs evolve.

Why choose PDM One?

With Duro, PLM is just the start. PDM One complements your PLM strategy by enabling efficient design workflows and secure data management without interruptions. It allows hardware teams to focus on design without worrying about accidental overwrites or version conflicts.

Duro’s PDM software integrates directly with CAD tools, so you can collaborate on files without leaving your design environment. With ITAR-compliant cloud storage, you maintain full control over your intellectual property, ensuring your data is secure and accessible only to authorized users.

Added Bonus: Duro-Hosted PDM

Duro is taking product data management further with its soon-to-be-released self-hosted PDM. Designed as a fresh alternative to platforms like Box, Dropbox, and Google Drive, this new PDM solution allows teams to store and manage their CAD PDM files with greater control while meeting the security needs of growing teams to ensure data remains protected and accessible.

The growing need for PDM

The PDM software market is growing rapidly, and there is no indication that it will slow down. As engineering teams scale and industries become more complex, the need for efficient data management tools has never been greater. With increasing demands for faster product development and quicker time to market, investing in the right PDM solution is no longer optional—it’s essential. Getting it right from the beginning can set the foundation for success.