TABLE OF CONTENTS

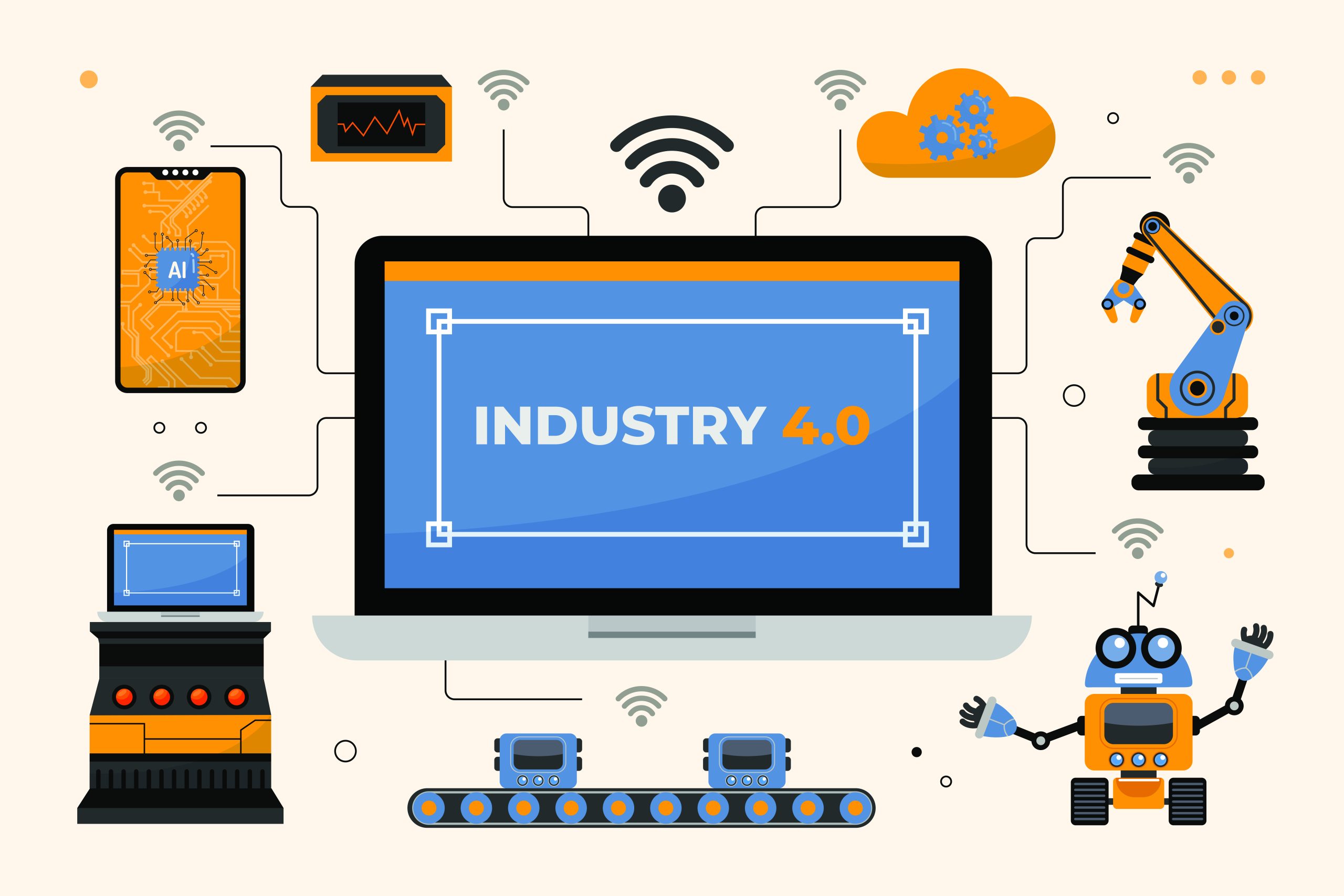

The Fourth Industrial Revolution (4IR) is here, ushering in a new era for the manufacturing industry. 4IR–also known as Industry 4.0–refers to the 21st-century industrial revolution marked by digital transformation and advanced manufacturing technology.

4IR is characterized by integrating technologies like artificial intelligence (AI), the Internet of Things (IoT), and robotics into industrial processes. Preparing for 4IR is not just an opportunity—it’s essential for staying competitive.

This article explores the opportunities presented by the Fourth Industrial Revolution, the transformative role of AI in manufacturing, and how companies can position themselves for success in this new era.

What is the Fourth Industrial Revolution (4IR)?

There have been three previous industrial revolutions: the first, in the late 18th century, was marked by steam power; the second, in the late 19th and early 20th centuries, by electricity; and the third, starting in the mid-20th century, by electronics and information technology.

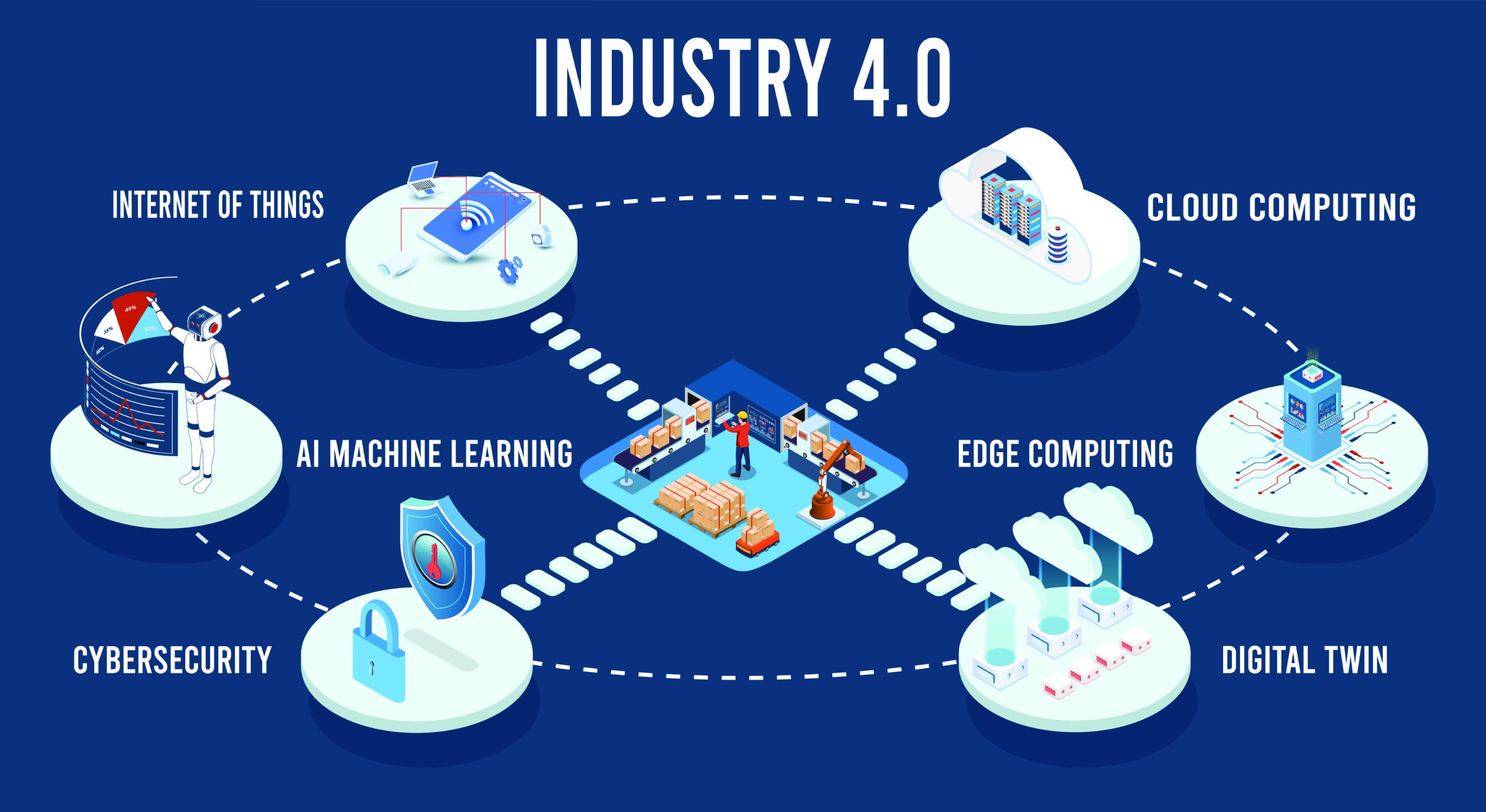

We are now at the outset of a fourth industrial revolution, marked by the integration of highly advanced digital technologies with traditional industrial systems. AI, IoT, robotics, big data, and advanced analytics drive this revolution. Together, these technologies create smarter, more connected systems capable of self-monitoring, optimizing, and even predicting outcomes without human intervention.

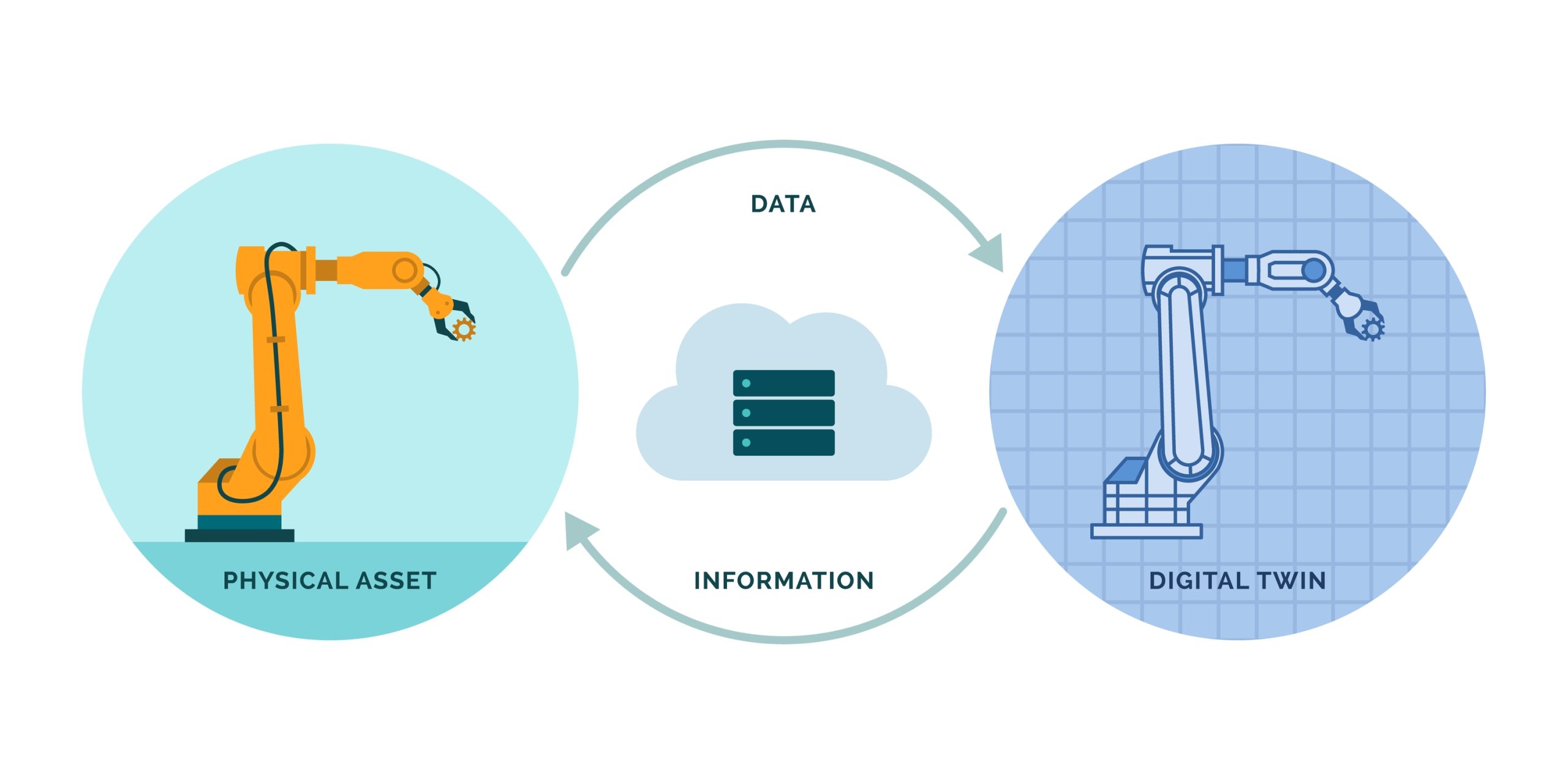

For manufacturers, 4IR is not just a technological upgrade: it’s a paradigm shift. Processes once reliant on manual labor are evolving into highly automated, data-driven workflows. Widespread adoption of AI, Internet of things, and robotics will enable the automation of repetitive tasks, the creation of digital twins for accurate and dynamic modeling, and the establishment of digital threads—data flows that connect every stage of a product’s lifecycle.

Combined with real-time data analytics, these technologies provide manufacturers with the insights needed to monitor, predict, and optimize performance across operations. By embracing 4IR, manufacturers can optimize operations across production lines, supply chains, and beyond.

The Manufacturing Landscape in 4IR

Broad shifts in workforce dynamics and global supply chain challenges are accelerating the adoption of advanced tools and systems, such as AI in supply chain management, which is core to the Fourth Industrial Revolution. These pressures are not just reshaping traditional processes—they drive the innovation and digital transformation defining 4IR.

Shifting Workforce Dynamics

As the baby boomer generation retires, the manufacturing industry faces a growing skills gap. Many companies rely heavily on a small group of highly experienced workers with decades of institutional knowledge and expertise. If these key individuals were to leave suddenly, critical processes could stall, highlighting the need to capture and transfer their knowledge before it’s lost.

To address this, manufacturers are leveraging digital tools to upskill their workforce and attract new talent. Automation and robotics handle repetitive or physically demanding tasks, freeing workers to focus on roles requiring critical thinking and collaboration.

Digitalization is also reshaping manufacturing’s image to be more modern and tech-forward, which appeals to a younger, tech-savvy generation of workers. For instance, augmented reality (AR) training programs allow employees to learn complex processes interactively, making onboarding faster and more engaging.

Global Supply Chain Challenges

COVID-19 and geopolitical tensions exposed vulnerabilities in traditional supply chains, prompting a shift toward resilience and adaptability. AI-powered tools have been helping manufacturers predict disruptions, analyze supplier risks, and optimize logistics. For example, during the COVID-19 pandemic, manufacturers used real-time analytics to pivot production and meet surging demands for essential goods.

The future of supply chains lies in digital twins–virtual models of the supply chain. These systems simulate scenarios to preempt challenges, ensuring smoother operations and better decision-making.

AI in Manufacturing & Hardware Product Development

AI is transforming every stage of manufacturing and hardware product development, driving efficiency, innovation, and precision. From automating production lines to reimagining product design, AI is reshaping how manufacturers operate in 4IR.

Automation in Production

AI-powered robotics and automation already allow manufacturers to achieve higher output with fewer resources. These technologies handle repetitive tasks like assembly and packaging with speed and precision.

Robots streamline production, reduce costs, and ensure quality through tools like smart cameras that catch defects early, minimizing waste and returns. Beyond the factory floor, robotic process automation (RPA) streamlines inventory management, eliminating bottlenecks.

Looking forward, collaborative robots (cobots) are expected to become even more integrated into production lines, working alongside humans to boost productivity, innovation, and safety.

Predictive Maintenance

AI minimizes downtime and extends equipment life by analyzing real-time machine data, which is already driving efficiency in industries like food production and aerospace. IoT sensors detect early signs of wear and tear, reducing the risk of an unexpected breakdown and ensuring optimal production conditions.

As connectivity improves with 5G, manufacturers can expect even faster, more reliable communication between machines, paving the way for greater agility and precision in factory operations.

Accelerating Product Development

4IR technologies like digital twins and AI-driven tools are revolutionizing design and testing. In industries like automotive and aerospace, digital twins—virtual replicas of physical products— simulate complex systems, reducing trial-and-error costs.

Generative design, powered by AI, optimizes components based on specific criteria, unlocking innovative possibilities in engineering. Generative design is already being tested in sectors like automotive and industrial machinery. These tools can suggest designs that balance strength, weight, and cost in ways traditional engineering cannot, unlocking new possibilities for innovation.

Intelligent Factories

AI is transforming traditional factories into intelligent systems capable of self-optimization and adaptation. Smart factories leverage IoT sensors, AI algorithms, and real-time data analytics to monitor operations, detect inefficiencies, and adjust without human intervention.

For example, AI systems can dynamically manage energy usage by analyzing production schedules and shifting power demands to off-peak hours, reducing costs. In automotive manufacturing, AI-enabled factories adjust production lines in real time to meet fluctuating demand, ensuring efficiency while minimizing waste.

As 5G connectivity expands, the potential for intelligent factories will grow even further, enabling seamless communication between machines and creating a new standard for operational excellence.

The Role of PLM in 4IR

Product Lifecycle Management (PLM) software is vital to manufacturers in 4IR. By fusing AI’s analytical power with PLM’s centralized framework, manufacturers can gain real-time insights into product data, streamline team collaboration, and achieve end-to-end visibility throughout the product development lifecycle. This will accelerate time to market, reduce errors, and improve decision-making.

As 4IR technologies continue to evolve, the integration of AI and PLM will become a cornerstone of smart manufacturing strategies. This will allow teams to optimize their Bill of Materials (BOM) for variables such as cost, lead time, physical attributes, and potential supply chain issues.

How AI Enhances Supply Chain Management & Resilience

AI-driven tools are already transforming supply chain management by offering real-time analytics, predictive insights, and comprehensive optimization capabilities. The progression of AI tools in 4IR will further optimize supply chain agility and resilience.

- AI and Supply Chain Visibility: AI-powered tools can enhance transparency, optimizing inventory and demand forecasting to prevent overproduction or shortages.

- Building Resilience: AI’s predictive capabilities can help manufacturers anticipate and address potential disruptions by analyzing risk factors such as material shortages, geopolitical tensions, or logistical delays.

- End-to-End Optimization: AI can enhance efficiency across the entire product lifecycle, from raw material procurement to final production. By identifying bottlenecks and inefficiencies, AI will ensure smoother transitions between supply chain stages, ultimately improving delivery timelines and reducing waste.

The Future of Manufacturing in 4IR

The Fourth Industrial Revolution offers endless opportunities for innovation in hardware. Companies that harness AI for smarter product design, more resilient supply chains, and efficient manufacturing processes will be positioned to lead the coming wave of industrial innovation.

At Duro, we believe the future of manufacturing is not just about keeping pace but about pushing the boundaries of what’s possible. As AI and other 4IR technologies continue transforming the industry, we remain committed to providing a flexible, innovative PLM solution for hardware and manufacturing organizations.

Together, we can embrace the possibilities of the Fourth Industrial Revolution and build a smarter, more connected future for manufacturing.