TABLE OF CONTENTS

ITAR compliance is critical for aerospace and defense companies that handle sensitive data and products. ITAR governs the export and handling of defense-related technologies, requiring companies in these industries to follow strict guidelines.

Building the right tech stack—including CAD (Computer-Aided Design) tools, PDM (Product Data Management), and PLM (Product Lifecycle Management) systems—is essential for meeting ITAR requirements.

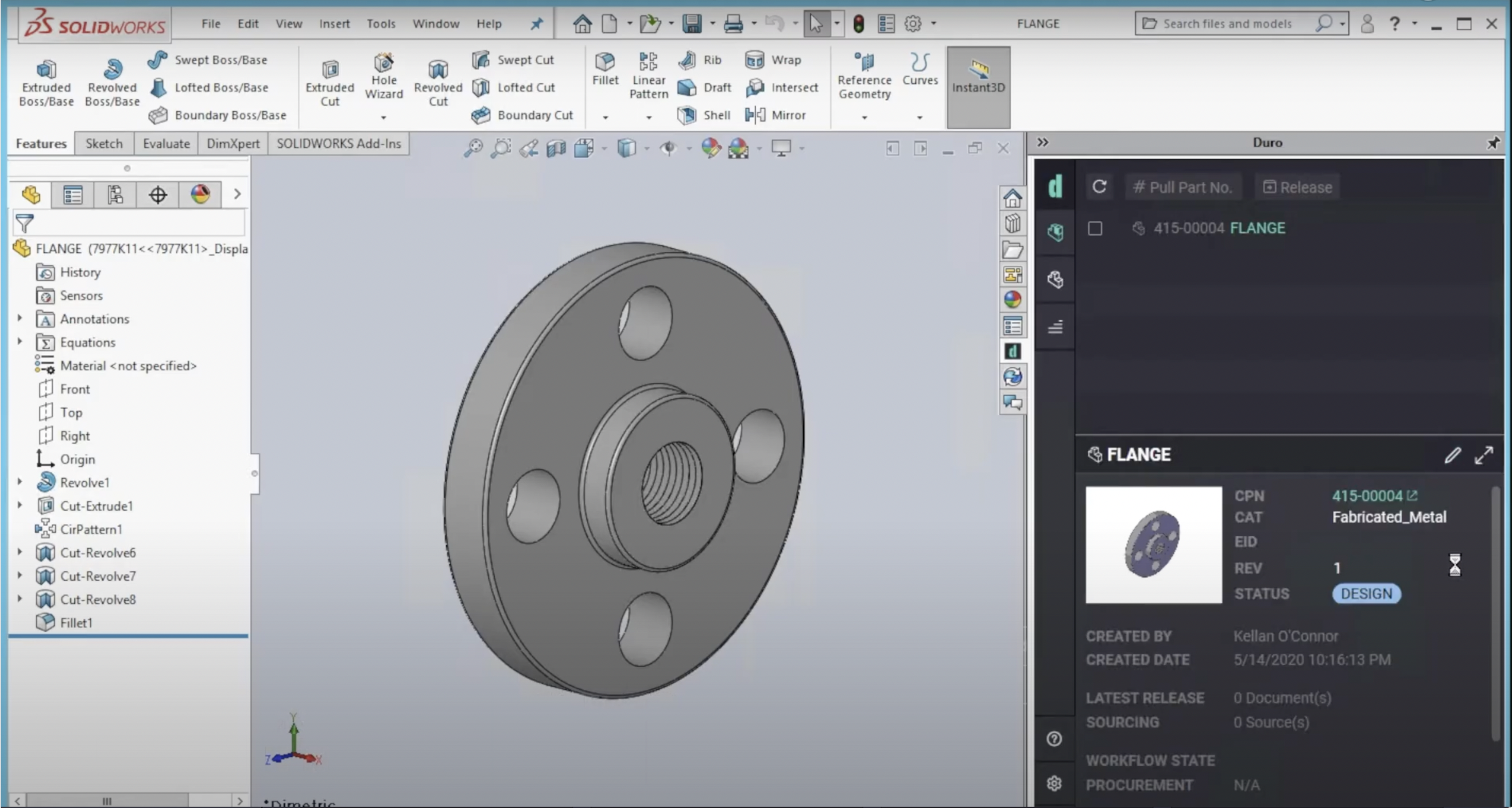

This article guides you through building an ITAR compliant tech stack using Duro’s PLM solution, with integrated CAD tools and Duro PDM One.

What is ITAR Compliance and Who Needs It?

ITAR (International Traffic in Arms Regulations) regulates the export of defense-related technologies to safeguard national security. Companies in the aerospace and defense industries must comply, such as those working with space technologies and military-grade electronics. This includes securely storing and managing data on U.S.-certified clouds and restricting access to U.S.-authorized personnel only.

What Do I Need to Do to Be ITAR Compliant?

To ensure ITAR compliance, you must follow these key steps:

- Host Data on a U.S.-Certified Cloud: Store defense-related data in a secure cloud platform like AWS GovCloud.

- Restrict Access to U.S.-Authorized Personnel: Ensure only personnel based in the U.S. can access sensitive data.

- Implement Secure Data Management and Auditing: Use tools that track and secure data flow to maintain compliance.

Refer to Duro’s ITAR Compliance Checklist for more details on compliance steps.

How to Build Your ITAR Compliant Tech Stack

Integrating CAD, PDM, and PLM systems is essential for aerospace and defense companies to ensure their product data remains accurate throughout the design and development. PLM works as the anchor in the stack, connecting upstream and downstream tools and managing workflows. Ensuring all these tools work together is just as important as ensuring they’re ITAR compliant. Look for solutions that help you remain compliant, working with vendors to host data securely..

eCAD and mCAD: Essential design tools

Aerospace engineers design components and assemblies using CAD software like SolidWorks, Siemens NX, and Altium. When combined with PLM, these tools ensure that the bill of materials is centralized in PLM and shared with downstream teams and applications.

- SolidWorks: When used on-premises, SolidWorks operates as an ITAR compliant solution, centralizing data storage and providing version control. SolidWorks integrates with ERP/MRP systems to manage design data securely.

- Altium: Altium Designer is available as an on-prem solution. However, by leveraging the Altium 365 GovCloud platform, aerospace companies can meet ITAR requirements by controlling access to sensitive data hosted on AWS GovCloud, ensuring only authorized U.S. personnel can access information.

- Siemens NX: When integrated with Teamcenter, Siemens NX allows administrators to manage access based on nationality and location, ensuring that ITAR-regulated data is only accessible to authorized personnel.

Do I need Teamcenter to leverage NX design data?

Duro’s NX add-in allows you to migrate your CAD data to its PLM tool. This option is valuable for mechanical engineers who rely on NX for design work but don’t need the complexity and extensive customizations that come with Teamcenter.

PDM: Data Management and Security

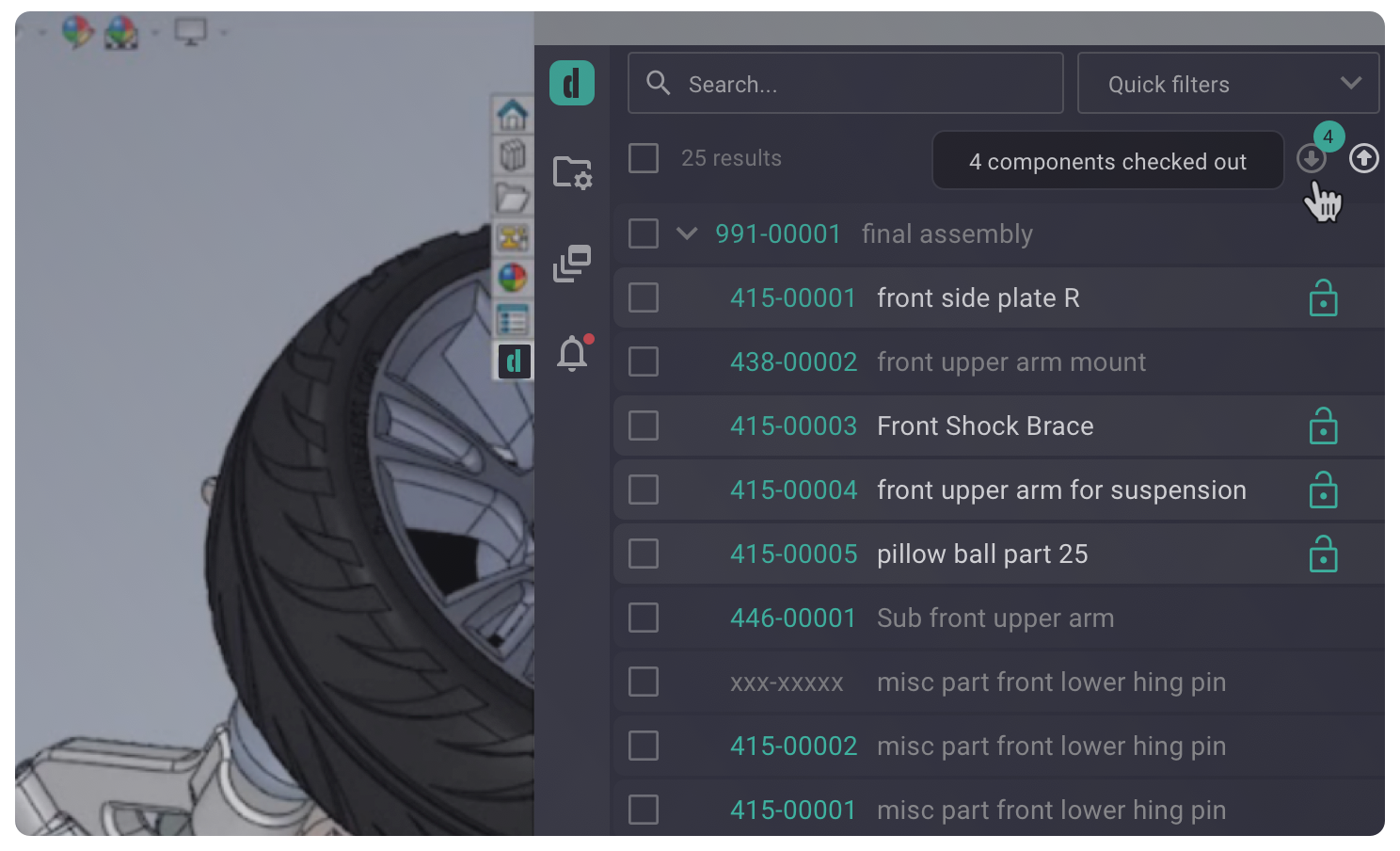

PDM centralizes and protects CAD design data, allowing aerospace engineers to collaborate efficiently by preventing accidental overwrites and managing file versions. Duro’s PDM One solution integrates directly with NX and SolidWorks, providing key features like check-in/check-out, file locking, and admin overwrite, ensuring secure access and version control. In an ITAR compliant environment, PDM is crucial for safeguarding sensitive design files and ensuring only authorized personnel can access and modify the data.

Do I need Solidworks PDM to use Duro PLM?

Duro PLM integrates with Solidworks Advanced PDM solution if you’re already using it. However, it’s not necessary to purchase this separately. Duro offers its own PDM solution, PDM One, that can be accessed as an ITAR compliant version. Duro PDM integrates directly with SolidWorks CAD and Siemens NX. These pre-built integrations eliminate the need for additional PDM software, simplifying your workflow and ensuring compliance.

PLM: The Backbone of the Tech Stack

PLM solutions are the foundation of any tech stack, connecting CAD data and ensuring smooth change order workflows, proper revision control, and real-time sourcing updates. Thorough documentation and traceability are essential for ITAR compliance. A robust and agile PLM system should centralize essential processes like BOM management, change orders, and revision tracking, allowing aerospace companies to manage product data efficiently and securely throughout the product lifecycle.

Post Design and Production: ERP & MES

Once the design is complete, ERP and MES systems manage production and ensure the product moves from concept to reality. Duro’s PLM connects seamlessly with downstream applications, but it’s essential to ensure each system is also ITAR compliant. Working with ITAR compliant vendors for ERP and MES, such as First Resonance or NetSuite, is critical to maintaining security throughout the entire product lifecycle.

ITAR Compliance with Duro

Choosing the right PLM that integrates with your CAD tools and incorporates PDM is a must for ITAR compliance. Duro offers a lightweight PLM solution for aerospace and defense companies, combining its powerful product lifecycle management software with PDM One to securely and efficiently manage your data.

Out-of-the-box integrations with leading CAD tools like SolidWorks and Siemens NX ensure your ITAR compliant tech stack is optimized from design through production. Duro’s flexible PLM also integrates with SolidWorks Advanced PDM for companies deeply invested in the SolidWorks ecosystem, ensuring your entire product development process remains ITAR compliant.

Duro PDM One

Duro PDM One integrates directly with mechanical CAD tools, such as Solidworks and NX, allowing engineers to protect their designs with features like:

- Check-In/Check-Out Functionality: Ensures collaborative work without the risk of overwriting files, allowing engineers to safely check files in and out for editing.

- File Locking and Admin Control: Full control over file edits, locking, and administrative oversight, ensuring data integrity is maintained.

- Cloud-Native Syncing: Duro users can integrate PDM One with Box to ensure ITAR compliance, ensuring your design files are backed up securely and accessible only to authorized team members.

Duro’s Agile PLM

Duro’s product lifecycle management solution is the backbone of an ITAR compliant tech stack, offering:

- Centralized Data Management: Manage all your product data in one place, from design files to BOMs and change orders.

- BOM Management: Keep track of parts, components, and revisions easily, ensuring you meet compliance and avoid costly mistakes.

- Pre-Built Integrations: Duro offers free integrations with top CAD tools like SolidWorks, Siemens NX, and Altium, allowing for smooth data transfer and version control. Additionally, these integrations are available out-of-the-box and can be deployed instantly without requiring lengthy customizations or consultants for set-up.

- Agile Workflows: Duro’s PLM supports agile workflows, helping aerospace teams stay flexible, make quick adjustments, and bring products to market faster, all while maintaining ITAR compliance.

Why Choose Duro?

Duro provides a comprehensive, ITAR compliant solution that simplifies managing your product data while offering robust security and integration with your existing tools. Whether you need PDM One for streamlined file management or a full PLM system to control every aspect of your product lifecycle, Duro ensures you stay compliant while reducing risks and costs. With Duro, you get a reliable, secure, and easy-to-use platform that meets ITAR requirements from end to end.