TABLE OF CONTENTS

In 2024, the global PLM (Product Lifecycle Management) market hit $26.24 billion, driven by aerospace, robotics, and industrial automation usage. As more industries move toward PLM 4.0 — AI, IoT, and big data will significantly improve how products are designed, manufactured, and maintained.

PLM 4.0 is deeply intertwined with Industry 4.0 and the digital transformation of manufacturing. AI-driven analytics and intelligent automation are improving efficiency, predictive insights, and real-time decision-making, helping manufacturers navigate supply chain instability, anticipate risks, and maintain production continuity.

This article explores how AI-enabled PLM and Industry 4.0 are evolving together, shaping the future of manufacturing and driving smarter, more connected product lifecycles.

What is Industry 4.0?

Industry 4.0, also known as the Fourth Industrial Revolution (4IR), is driving digital transformation in manufacturing through AI, IoT, and real-time data analytics. By integrating these technologies, companies can optimize production, reduce inefficiencies, and enhance adaptability to supply chain demands and market fluctuations.

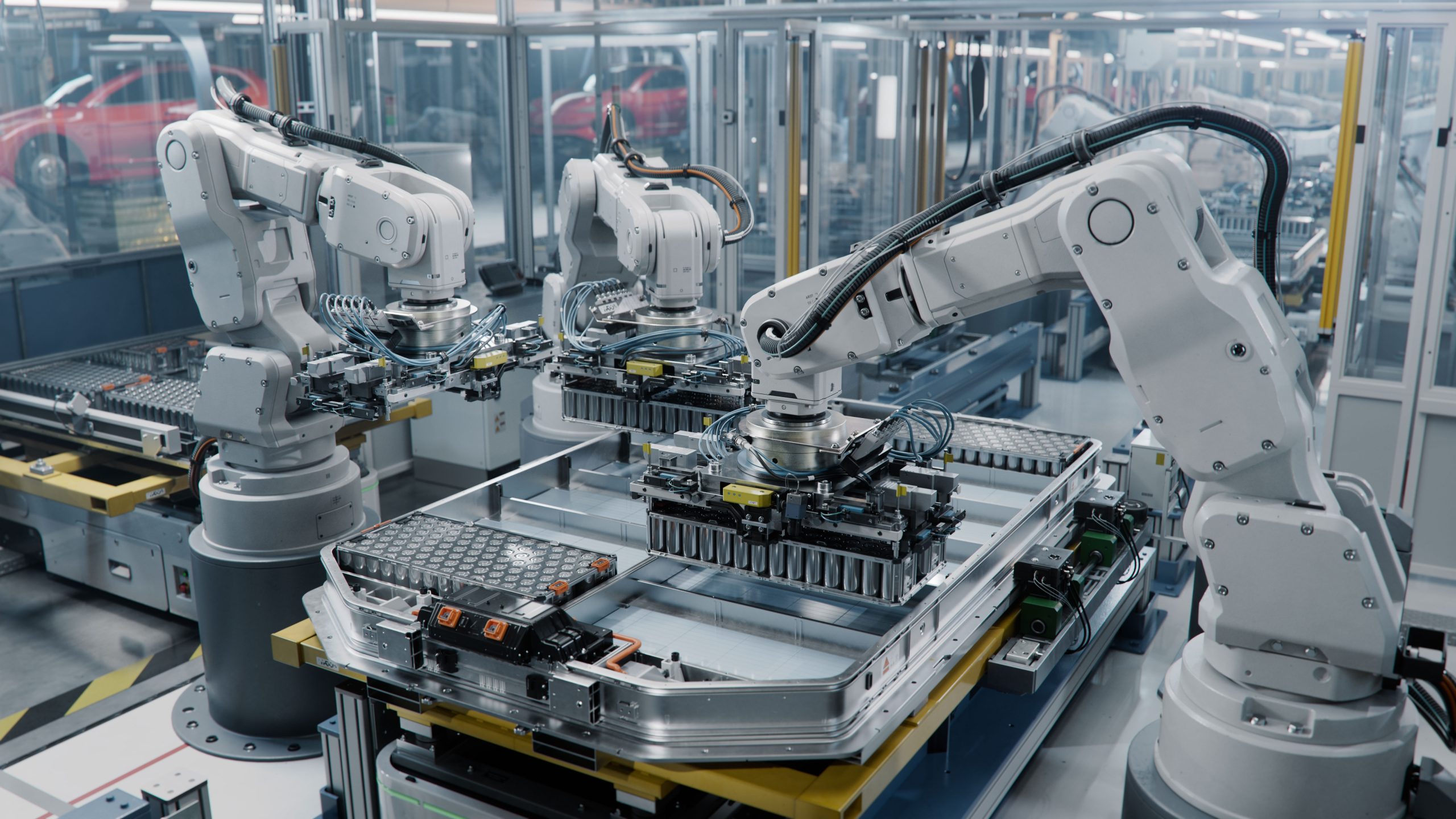

With billions of IoT devices connected across industries like robotics and industrial automation, manufacturers gain real-time visibility into operations. This enables predictive maintenance, improved uptime, and smarter decision-making. AI accelerates these advancements, making product development and production faster and more efficient.

“What’s exciting about 4IR is the sheer magnitude and pace of new technologies empowering hardware design and manufacturing companies. It allows them to move faster, taking products from a paper-napkin sketch to mass production more efficiently than ever before.”

Michael Corr, Duro CEO

What is PLM & PLM 4.0?

PLM (Product Lifecycle Management) systems manage a product from conception through design, manufacturing, and retirement. Manufacturers rely on PLM software to streamline collaboration, maintain a single source of truth, and integrate supply chain data—improving efficiency, reducing costs, ensuring compliance, and accelerating innovation cycles.

PLM 4.0 represents the next evolution, incorporating AI, IoT, and big data to create a more connected, intelligent, and automated product development process. AI-driven automation reduces manual tasks, while digital twins and digital threads enable real-time simulation, predictive maintenance, and improved traceability. Enhanced data integration supports smarter decision-making at every stage of the product lifecycle.

AI-Powered PLM

Integrating AI into PLM software will redefine how products are designed, tested, and brought to market. AI-driven analytics can now detect risks in product development, helping manufacturers reduce failures and streamline compliance monitoring. Automating these processes ensures regulatory standards are met and minimizes costly production errors.

AI-powered PLM changes how today’s engineers interact with vast data repositories by enabling natural language search capabilities and eliminating the need for complex key-value pair queries. Generative AI tools enhance BOM analysis, optimizing material selection for cost, lead time, or weight, ensuring more efficient product development.

AI significantly advances overall product lifecycle management by generating new product iterations based on existing design data, supply chain information, and customer feedback. Advanced demand forecasting allows manufacturers to align development processes with market needs. AI-driven supply chain monitoring can identify potential disruptions, allowing companies to make proactive decisions about component sourcing and production adjustments.

“As companies embrace Industry 4.0, they need solutions beyond data storage to enhance decision-making, streamline supply chain management, and accelerate innovation. PLM 4.0, powered by AI-driven automation, predictive analytics, and digital threads, enables engineering teams to move faster while reducing complexity. Duro is delivering an AI-enabled PLM that is accessible and helps manufacturers optimize every stage of the product lifecycle—from concept to production.”

Jon Stevenson, Former GrabCAD VP

IoT and PLM

The Internet of Things (IoT) is a network of connected devices that collect and exchange real-time data, driving automation and smarter decision-making across industries. IoT improves efficiency, reduces downtime, and optimizes workflows by providing continuous performance insights from connected machinery.

When integrated with PLM, IoT data enhances reliability, productivity, and operational efficiency. Companies like Rapid Robotics use AI-driven automation with PLM to connect IoT-enabled robotics, eliminate repetitive tasks, and improve efficiency. As modern machinery incorporates IoT capabilities, manufacturers can analyze performance data within PLM, applying insights to streamline operations and enhance product reliability.

One of the biggest shifts in manufacturing is the growing connectivity of physical systems through IoT. While modern machines generate valuable operational data, much of it remains siloed in dashboards or disconnected from critical decision-making, limiting its full impact.

PLM goes beyond data collection—it actively integrates information into the product lifecycle. If a testing plan requires a container’s pressure to stay below a set threshold or an engine’s temperature within safe limits, IoT and PLM can automatically validate, record, and apply this data, improving quality control, predictive maintenance, and overall performance.

Digital Twins

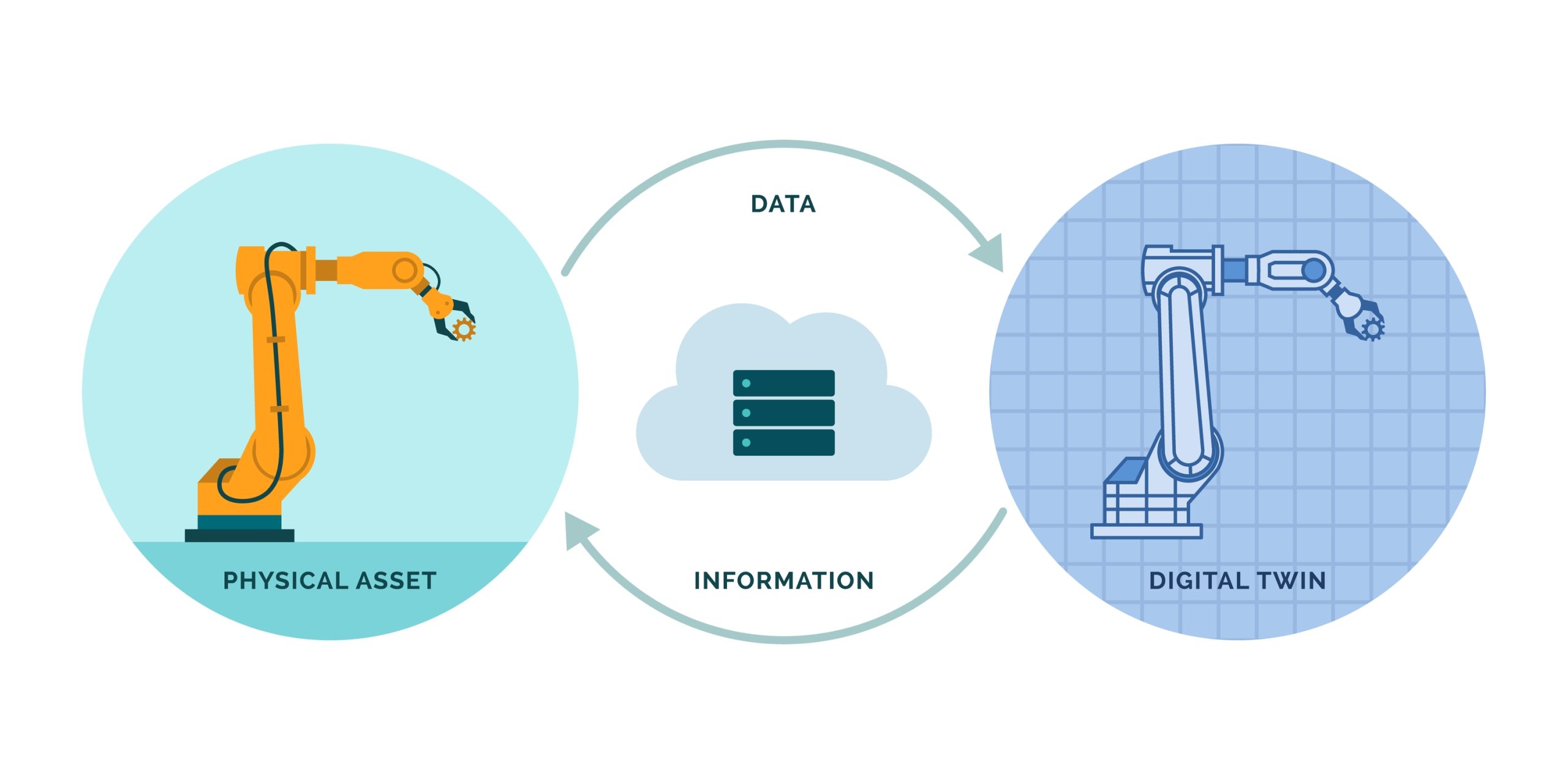

Digital twins are virtual models of physical products that provide real-time insights for performance optimization and predictive maintenance. These models allow manufacturers to simulate conditions, test improvements, and identify potential issues before they impact production. This level of insight reduces downtime and improves overall operational efficiency.

By integrating digital twins into PLM, manufacturers can proactively address failures before they occur. Virtual testing environments allow continuous innovation while cutting costs and accelerating development cycles. This digital-first approach significantly enhances how companies approach product testing and refinement.

Digital Threads

Digital threads ensure data flows across the entire product lifecycle, providing end-to-end traceability for product changes. They give every department access to up-to-date product information, reducing errors and miscommunication.

Digital threads improve decision-making by structuring unstructured data into actionable insights. By integrating these capabilities into PLM software, manufacturers create a more transparent and efficient development process, enabling greater agility in responding to market changes.

Digital threads reduce reliance on third-party suppliers and streamline version control. Engineers often spend too much time rechecking values, an issue digital threads help resolve by centralizing knowledge and improving data accessibility. By ensuring critical insights aren’t lost in scattered spreadsheets or undocumented workflows, digital threads free engineers to focus on innovation and efficiency.

AI-enhanced Data Management

A Hexagon survey found that 98% of manufacturers face data challenges hindering innovation and time to market. Poor data quality and availability slow the adoption of AI, automation, and digital twins, impacting collaboration and productivity. The same study found that nearly 40% of manufacturers lag in automation, falling behind competitors that leverage data-driven efficiency.

These challenges contribute to supply chain disruptions, where global supply networks remain vulnerable to external factors like political instability, weather conditions, and fluctuating market demands. Predicting part availability, pricing, and delivery timelines accurately has long been a struggle for manufacturers. AI-driven analytics can now accurately aggregate and interpret disparate data sources—many of which may be inconsistent or unreconciled.

This is where AI significantly outperforms its predecessors, like machine learning and advanced algorithms, by processing massive datasets, identifying patterns, and generating predictive insights. With the ability to analyze historical and real-time data, AI helps manufacturers anticipate part availability, forecast delivery timelines, and optimize pricing strategies, keeping them competitive in volatile markets.

PLM 4.0 — The Future of Manufacturing

Traditional PLM tools weren’t built for fast-paced product development. PLM 4.0 introduces faster agile workflows that let engineers focus on innovation instead of outdated, manual processes. Hardware teams now demand the same speed, flexibility, and collaboration that software teams have long enjoyed—there’s a reason we hear hardware is the new software so often.

Large manufacturers still rely on spreadsheets and legacy software to track programs and manage data—systems unfit for modern hardware development. PLM 4.0 eliminates these inefficiencies with an AI-driven, digital-first approach, enabling real-time collaboration, automation, and smarter decision-making. As the manufacturing industry continues its digital transformation, hardware engineering will increasingly resemble software development.

PLM 4.0 integrates AI-powered analytics, digital threads, and IoT for secure, efficient data management. These technologies redefine how manufacturers develop, produce, and maintain products, keeping them competitive in an industry that evolves daily. The companies that embrace AI-enabled PLM will drive the next wave of industrial innovation, building faster, more resilient supply chains.